HT11W 系列机械上调式三辊对称式带液压卸料卷板机应用场地和特点的介绍:

金属结构加工车间:用于制造各种金属结构件,如桥梁、建筑框架、机械外壳等。通过卷制不同规格的板材,为结构件的制造提供基础部件。

压力容器制造企业:在制造压力容器时,需要将钢板卷制成圆柱形或其他形状的筒体。该卷板机能够满足压力容器制造中对板材卷制精度和质量的要求,确保筒体的尺寸精度和表面质量,符合相关安全标准。

管道加工行业:对于一些大型管道的制造,需要将宽幅板材卷制成圆形管道。HT11W 系列卷板机可用于卷制不同直径和壁厚的管道,广泛应用于石油、化工、给排水等行业的管道制造。

船舶制造领域:船舶的船体结构中包含大量的曲面钢板,需要通过卷板机将板材卷制出合适的形状,以满足船体外形和结构强度的要求。该卷板机在船舶制造中可用于卷制船侧板、船底板等各种曲面构件。

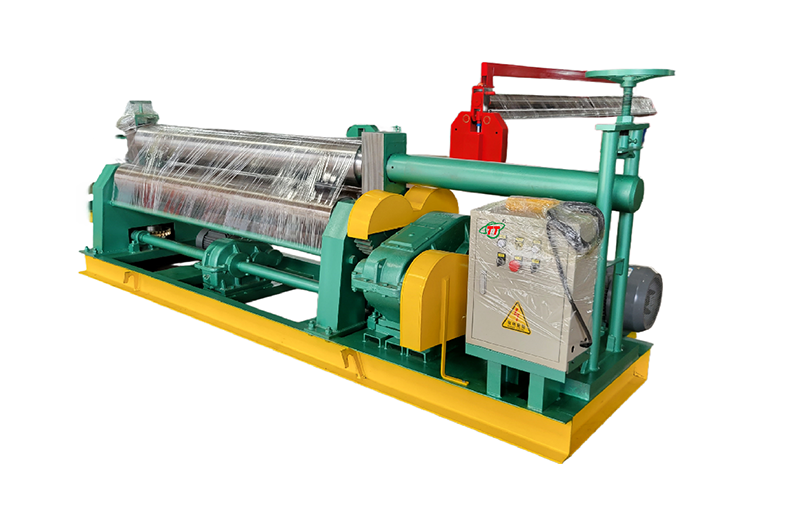

机械上调式结构:采用机械上调式设计,上辊可垂直升降,方便调整对板材的压力和卷制曲率半径。这种结构具有较高的刚性和稳定性,能够承受较大的卷制力,适用于卷制各种厚度和材质的板材。

三辊对称式布局:三个辊筒呈对称分布,使得板材在卷制过程中受力均匀,能够有效保证卷制后的圆筒或其他形状的精度和圆度。同时,对称式布局也便于操作和调整,提高了卷板机的工作效率。

液压卸料装置:配备液压卸料系统,卸料过程平稳、安全、高效。通过液压驱动,能够精确控制卸料动作,避免在卸料过程中对卷制好的工件造成损伤。液压卸料装置大大减轻了工人的劳动强度,提高了生产效率,尤其适用于大型、重型板材卷制后的卸料作业。

广泛的适用性:可以卷制多种材质的板材,如碳钢、不锈钢、合金钢等,满足不同行业对材料的要求。同时,能够卷制不同厚度和宽度的板材,通过调整辊筒的间距和压力,可以实现多种规格板材的卷制,具有较强的通用性和灵活性。

操作简便:该卷板机的控制系统设计合理,操作界面简洁明了,工人经过简单培训即可熟练操作。具备多种操作模式,可根据实际生产需求选择手动、半自动或自动操作,提高了设备的易用性和生产效率。

高精度卷制:采用先进的加工工艺和高精度的零部件制造,保证了卷板机的各项精度指标。在卷制过程中,能够精确控制板材的卷曲半径和形状精度,满足各种高精度产品的卷制要求,为后续的加工和装配提供了良好的基础。

板材卷制:

送料:将待卷制的板材送入三辊卷板机。一般通过人工或自动送料装置,使板材前端进入上下辊之间的间隙。

预弯:三辊卷板机的上辊可以垂直升降,下辊固定,两侧辊可水平移动。预弯时,上辊下降,对板材端部施加压力,两侧辊向中间移动,使板材端部产生一定的弯曲变形,形成预弯效果。这个过程主要是为了消除板材端部的直线段,使其在后续卷制过程中能够更好地贴合辊筒。

卷制:预弯完成后,上辊继续下降,使板材与上、下辊紧密接触。然后,上辊或下辊(通常上辊可驱动)转动,带动板材在三个辊筒之间滚动。两侧辊通过水平移动调整位置,使板材逐渐卷曲成所需的曲率半径。在卷制过程中,三个辊筒对板材施加的压力和摩擦力使板材发生塑性变形,从而实现卷制工艺。

成型:随着板材的不断卷制,板材逐渐卷成圆筒形或其他形状。通过控制上辊的升降、两侧辊的水平移动以及辊筒的转动,可实现不同曲率半径和形状的卷制要求。

液压卸料:

液压系统:该卷板机配备了液压系统,主要由液压泵、液压缸、控制阀和油箱等组成。液压泵提供动力,将液压油从油箱中吸出并加压,通过管路输送到液压缸。

卸料操作:当板材卷制完成后,上辊上升至一定高度,以确保卷制好的圆筒可以顺利卸料。然后,启动液压卸料装置,液压油进入卸料液压缸,推动液压缸的活塞运动。液压缸的活塞杆与卸料装置(如卸料架或卸料辊)相连,活塞的运动带动卸料装置将卷制好的圆筒从卷板机的辊筒上卸下。在卸料过程中,液压系统可以精确控制卸料装置的动作,确保卸料平稳、安全,避免圆筒在卸料过程中受到损伤。

复位:卸料完成后,液压系统将液压缸的活塞收回,使卸料装置恢复到初始位置,准备下一次卷制和卸料操作。

HT11W系列机械上调式三辊对称式卷板机

一、性能特点:

HT11W系列机械上调式对称三辊卷板机为结构型式为三辊对称式,上辊在两下辊中央对称位置作垂直升降运动,通过丝杆丝母蜗杆传动而获得,两下辊作旋转运动,通过减速机的输出齿轮与下辊齿轮啮合,为卷制板材提供扭矩。该机缺点是板材端部需借助其它设备进行预弯。

二、主要技术参数:

| 规格型号 | 最大卷板厚度(mm) | 最大卷板宽度(mm) | 板材屈服极限(MPa) | 卷板速度(m/min) | 满载最小卷板直径 (mm) | 上辊直径(mm) | 下辊直径(mm) | 边辊直径(mm) | 主电机功率(kw) |

| HT11W-6*1500 | 6 | 1500 | 245 | 5 | 450 | 160 | 160 | 250 | 4 |

| HT11W-6*2000 | 6 | 2000 | 245 | 4.5 | 450 | 185 | 170 | 250 | 5.5 |

| HT11W-4*3200 | 4 | 3200 | 245 | 4.5 | 450 | 185 | 170 | 250 | 5.5 |

| HT11W-1*2000 | 12 | 2000 | 245 | 4 | 600 | 240 | 180 | 280 | 7.5 |

| HT11W-8*2500 | 8 | 2500 | 245 | 4 | 600 | 240 | 180 | 280 | 7.5 |

| HT11W-12*3200 | 12 | 3200 | 245 | 4 | 700 | 280 | 250 | 360 | 15 |

| HT11W-16*2500 | 16 | 2500 | 245 | 4 | 700 | 280 | 240 | 360 | 15 |

| HT11W-20*2000 | 20 | 2000 | 245 | 4 | 700 | 280 | 240 | 360 | 15 |

| HT11W-25*2000 | 25 | 2000 | 245 | 4 | 850 | 330 | 270 | 440 | 18.5 |

| HT11W-20*2500 | 20 | 2500 | 245 | 4 | 850 | 340 | 280 | 440 | 18.5 |

| HT11W-16*3200 | 16 | 3200 | 245 | 4 | 850 | 340 | 280 | 440 | 18.5 |

备注:表格中所列数据均为标准配置时的对应数据。

本资料仅供选择时参考,对本公司不构成约束力。外观及数据如有改动,恕不另行通知。