服务热线

13905146213

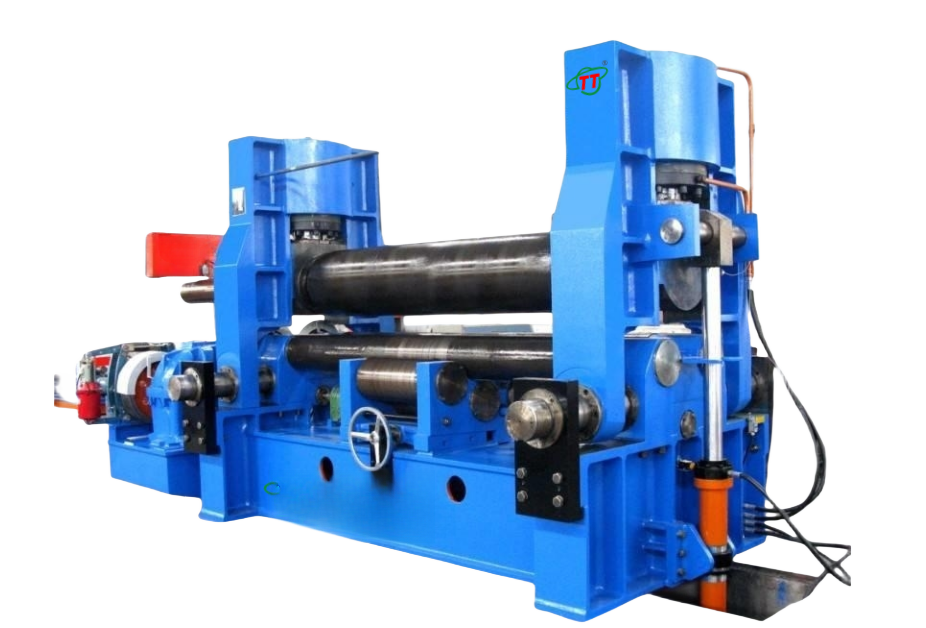

HT11S系列上辊万能式卷板机介绍

5、上辊万能式卷板机的工作原理是通过电机驱动带动各个辊子转动,利用辊子之间的相互作用对板材进行弯曲卷制,具体如下:

7、 根据用途或用户要求,具有经济型数显机型、TC数控机型选。

二、技术参数:

| 规格型号 | 上辊加压力(Tons) | 最大板厚 | 板幅(mm) | 上辊直径(mm) | 下辊直径(mm) | 中心距(mm) | 电动机(kw) | |||

| 端曲(mm) | 中央(mm) | 驱动用 | 油压用 | 移动用 | ||||||

| HT11S-8*1500 | 25 | 6 | 8 | 1500 | 175 | 125 | 160 | 3 | 2.2 | 0.75 |

| HT11S-6*2000 | 25 | 4.5 | 6 | 2000 | 195 | 125 | 160 | 3 | 2.2 | 0.75 |

| HT11S-8*1500 | 30 | 6.5 | 8 | 1500 | 185 | 125 | 160 | 3 | 2.2 | 0.75 |

| HT11S-8*000 | 30 | 5.5 | 8 | 2000 | 205 | 125 | 160 | 3 | 2.2 | 0.75 |

| HT11S-10*1500 | 37 | 8 | 10 | 1500 | 205 | 135 | 180 | 4 | 2.2 | 0.75 |

| HT11S-8*2000 | 37 | 6.5 | 8 | 2000 | 220 | 135 | 180 | 4 | 2.2 | 0.75 |

| HT11S-8*2500 | 37 | 5.7 | 8 | 2500 | 235 | 135 | 180 | 4 | 2.2 | 0.75 |

| HT11S-12*1500 | 45 | 9 | 11 | 1500 | 215 | 135 | 180 | 4 | 2.2 | 0.75 |

| HT11S-10*2000 | 45 | 7.5 | 10 | 2000 | 235 | 135 | 180 | 4 | 2.2 | 0.75 |

| HT11S-10*2500 | 45 | 6.5 | 9 | 2500 | 245 | 135 | 180 | 4 | 2.2 | 0.75 |

| HT11S-12*2000 | 55 | 9 | 11 | 2000 | 245 | 145 | 200 | 5.5 | 4 | 0.75 |

| HT11S-10*2500 | 55 | 8 | 10 | 2500 | 255 | 145 | 200 | 5.5 | 4 | 0.75 |

| HT11S-10*3000 | 55 | 7 | 10 | 3000 | 275 | 145 | 200 | 5.5 | 4 | 0.75 |

| HT11S-12*2000 | 65 | 10 | 12 | 2000 | 250 | 145 | 200 | 5.5 | 4 | 0.75 |

| HT11S-12*2500 | 65 | 9 | 12 | 2500 | 265 | 145 | 200 | 5.5 | 4 | 0.75 |

| HT11S-12*3200 | 65 | 9 | 12 | 3200 | 265 | 145 | 200 | 5.5 | 4 | 0.75 |

| 规格型号 | 上辊加压力(Tons) | 最大板厚 | 板幅(mm) | 上辊直径(mm) | 下辊直径(mm) | 中心距(mm) | 电动机(kw) | |||

| 端曲(mm) | 中央(mm) | 驱动用 | 油压用 | 移动用 | ||||||

| HT11S-15*2000 | 75 | 12 | 15 | 2000 | 255 | 150 | 245 | 7.5 | 4 | 1.1 |

| HT11S-14*2500 | 75 | 10 | 14 | 2500 | 270 | 150 | 245 | 7.5 | 4 | 1.1 |

| HT11S-13*3000 | 75 | 9 | 13 | 3000 | 290 | 150 | 245 | 7.5 | 4 | 1.1 |

| HT11S-16*2500 | 100 | 13 | 16 | 2500 | 300 | 165 | 270 | 15 | 5.5 | 1.5 |

| HT11S-16*3000 | 100 | 11 | 16 | 3000 | 325 | 165 | 270 | 15 | 5.5 | 1.5 |

| HT11S-20*2500 | 130 | 16 | 20 | 2500 | 330 | 180 | 300 | 15 | 5.5 | 2.2 |

| HT11S-18*3000 | 130 | 14 | 18 | 3000 | 350 | 180 | 300 | 15 | 5.5 | 2.2 |

| HT11S-22*2500 | 160 | 18 | 22 | 2500 | 360 | 200 | 330 | 18.5 | 7.5 | 2.2 |

| HT11S-20*3000 | 160 | 16 | 20 | 3000 | 375 | 200 | 330 | 18.5 | 7.5 | 2.2 |

| HT11S-18*3500 | 160 | 14 | 18 | 3500 | 390 | 200 | 330 | 18.5 | 7.5 | 2.2 |

| HT11S-24*2500 | 190 | 21 | 24 | 2500 | 380 | 220 | 360 | 22 | 7.5 | 4 |

| HT11S-22*3000 | 190 | 19 | 22 | 3000 | 400 | 220 | 360 | 22 | 7.5 | 4 |

| HT11S-20*3500 | 190 | 16 | 19 | 3500 | 410 | 220 | 360 | 22 | 7.5 | 4 |

| HT11S-30*2500 | 230 | 25 | 29 | 2500 | 410 | 235 | 380 | 30 | 11 | 4 |

| HT11S-27*3000 | 230 | 22 | 27 | 3000 | 425 | 235 | 380 | 30 | 11 | 4 |

| HT11S-25*3500 | 230 | 21 | 25 | 3500 | 440 | 235 | 380 | 30 | 11 | 4 |

| HT11S-30*2500 | 270 | 28 | 30 | 2500 | 430 | 250 | 400 | 30 | 11 | 4 |

| HT11S-30*3000 | 270 | 25 | 30 | 3000 | 450 | 250 | 400 | 30 | 11 | 4 |

| HT11S-30*3500 | 270 | 23 | 30 | 3500 | 470 | 250 | 400 | 30 | 11 | 4 |

| HT11S-25*4000 | 270 | 20 | 25 | 4000 | 490 | 250 | 400 | 30 | 11 | 4 |

| HT11S-36*2500 | 320 | 30 | 36 | 2500 | 460 | 260 | 420 | 37 | 15 | 5.5 |

| HT11S-30*3000 | 320 | 28 | 30 | 3000 | 480 | 260 | 420 | 37 | 15 | 5.5 |

| HT11S-28*3500 | 320 | 25 | 28 | 3500 | 500 | 260 | 420 | 37 | 15 | 5.5 |

| HT11S-26*4000 | 320 | 22 | 26 | 4000 | 520 | 260 | 420 | 37 | 15 | 5.5 |

| HT11S-40*2500 | 380 | 35 | 39 | 2500 | 500 | 275 | 460 | 45 | 22 | 5.5 |

| HT11S-35*3000 | 380 | 32 | 35 | 3000 | 510 | 275 | 460 | 45 | 22 | 5.5 |

| HT11S-32*3500 | 380 | 28 | 32 | 3500 | 530 | 275 | 460 | 45 | 22 | 5.5 |

| HT11S-30*4000 | 380 | 25 | 30 | 4000 | 550 | 275 | 460 | 45 | 22 | 5.5 |

| HT11S-40*2500 | 430 | 40 | 43 | 2500 | 520 | 290 | 500 | 55 | 22 | 7.5 |

| HT11S-38*3000 | 430 | 35 | 38 | 3000 | 540 | 290 | 500 | 55 | 22 | 7.5 |

| HT11S-36*3500 | 430 | 30 | 36 | 3500 | 560 | 290 | 500 | 55 | 22 | 7.5 |

| HT11S-32*4000 | 430 | 28 | 32 | 4000 | 580 | 290 | 500 | 55 | 22 | 7.5 |

3、大型上辊万能式卷板机技术参数:

| 规格型号 | 上辊加压力Tons | 最大板厚 | 板幅mm | 上辊直径mm | 下辊直径mm | 中心距mm | 电动机kw | |||

| 端曲mm | 中央mm | 驱动用 | 油压用 | 移动用 | ||||||

| HT11S-45*3000 | 540 | 40 | 45 | 3000 | 590 | 340 | 610 | 55 | 22 | 11 |

| HT11S-40*4000 | 540 | 35 | 40 | 4000 | 630 | 340 | 610 | 55 | 22 | 11 |

| HT11S-36*5000 | 540 | 30 | 36 | 5000 | 670 | 340 | 610 | 55 | 22 | 15 |

| HT11S-32*6000 | 540 | 28 | 32 | 6000 | 700 | 340 | 610 | 55 | 22 | 15 |

| HT11S-55*3000 | 610 | 45 | 55 | 3000 | 620 | 360 | 650 | 75 | 30 | 15 |

| HT11S-45*4000 | 610 | 40 | 45 | 4000 | 660 | 360 | 650 | 75 | 30 | 15 |

| HT11S-40*5000 | 610 | 32 | 40 | 5000 | 700 | 360 | 650 | 75 | 30 | 15 |

| HT11S-36*6000 | 610 | 30 | 36 | 6000 | 730 | 360 | 650 | 75 | 30 | 15 |

| HT11S-60*3000 | 690 | 50 | 60 | 3000 | 650 | 380 | 700 | 75 | 30 | 15 |

| HT11S-50*4000 | 690 | 45 | 50 | 4000 | 700 | 380 | 700 | 75 | 30 | 15 |

| HT11S-45*5000 | 690 | 38 | 45 | 5000 | 740 | 380 | 700 | 75 | 30 | 15 |

| HT11S-40*6000 | 690 | 35 | 40 | 6000 | 760 | 380 | 700 | 75 | 30 | 15 |

| HT11S-70*3000 | 850 | 60 | 70 | 3000 | 710 | 420 | 780 | 75 | 37 | 15 |

| HT11S-55*4000 | 850 | 50 | 55 | 4000 | 750 | 420 | 780 | 90 | 37 | 15 |

| HT11S-50*5000 | 850 | 42 | 50 | 5000 | 790 | 420 | 780 | 90 | 37 | 15 |

| HT11S-45*6000 | 850 | 38 | 45 | 6000 | 820 | 420 | 780 | 90 | 37 | 15 |

| HT11S-75*3000 | 930 | 65 | 75 | 3000 | 740 | 440 | 820 | 90 | 37 | 15 |

| HT11S-60*4000 | 930 | 55 | 60 | 4000 | 780 | 440 | 820 | 90 | 37 | 15 |

| HT11S-55*5000 | 930 | 45 | 55 | 5000 | 820 | 440 | 820 | 90 | 37 | 18.5 |

| HT11S-50*6000 | 930 | 42 | 50 | 6000 | 850 | 440 | 820 | 90 | 37 | 18.5 |

| HT11S-80*3000 | 1050 | 70 | 80 | 3000 | 770 | 460 | 880 | 90 | 37 | 18.5 |

| HT11S-65*4000 | 1050 | 60 | 65 | 4000 | 810 | 460 | 880 | 90 | 37 | 18.5 |

| HT11S-60*5000 | 1050 | 50 | 60 | 5000 | 850 | 460 | 880 | 90 | 37 | 18.5 |

| HT11S-55*6000 | 1050 | 45 | 55 | 6000 | 890 | 460 | 880 | 90 | 37 | 18.5 |

| HT11S-85*3000 | 1150 | 75 | 85 | 3000 | 800 | 480 | 920 | 110 | 45 | 18.5 |

| HT11S-70*4000 | 1150 | 65 | 70 | 4000 | 840 | 480 | 920 | 110 | 45 | 18.5 |

| HT11S-65*5000 | 1150 | 55 | 65 | 5000 | 890 | 480 | 920 | 110 | 45 | 22 |

| HT11S-60*6000 | 1150 | 50 | 60 | 6000 | 930 | 480 | 920 | 110 | 45 | 22 |

| HT11S-100*3000 | 1350 | 90 | 100 | 3000 | 860 | 480 | 920 | 110 | 45 | 22 |

| HT11S-80*4000 | 1350 | 75 | 80 | 4000 | 900 | 520 | 1000 | 110 | 45 | 22 |

| HT11S-70*5000 | 1350 | 65 | 70 | 5000 | 940 | 520 | 1000 | 110 | 45 | 22 |

| HT11S-65*6000 | 1350 | 60 | 65 | 6000 | 980 | 520 | 1000 | 110 | 45 | 22 |

| HT11S-115*3000 | 1600 | 100 | 115 | 3000 | 900 | 560 | 1080 | 132 | 55 | 30 |

| HT11S-100*4000 | 1600 | 85 | 100 | 4000 | 940 | 560 | 1080 | 132 | 55 | 30 |

| HT11S-125*3000 | 1800 | 110 | 125 | 3000 | 960 | 600 | 1120 | 160 | 75 | 37 |

| HT11S-110*4000 | 1800 | 95 | 110 | 4000 | 990 | 600 | 1120 | 160 | 75 | 37 |

| HT11S-120*4000 | 2300 | 100 | 120 | 4000 | 990 | 640 | 1280 | 150 | 55 | 37 |

本资料所列数据为参考数据,如与机床实际数据不符,应以机床实际数据为准,

以上参数如有变动,恕不另行通知,本公司保留对此资料的最终解释权!