服务热线

13905146213

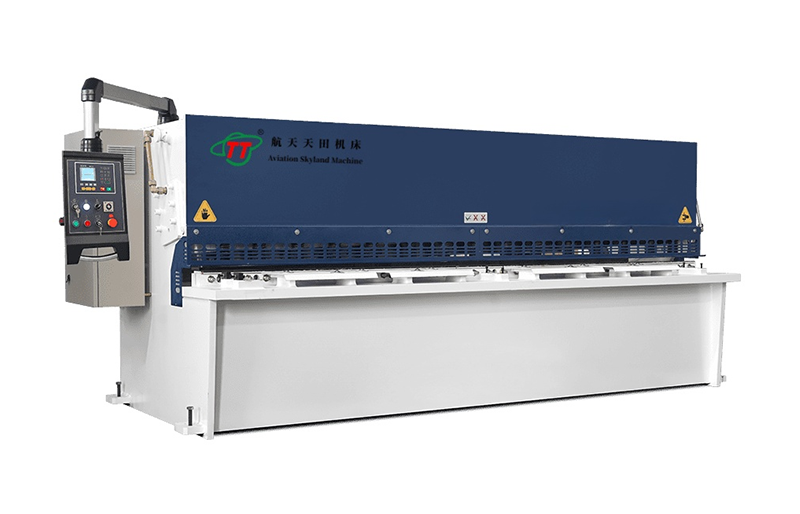

一、HT12K系列数控摆式剪板机性能特点( Performance Characteristics of HT12K Series CNC Pendulum Shearing Machine):

9、后挡料由E21S或MD11-1数控系统控制。

二、 H12k液压数控摆式剪板机技术参数表(Technical Parameter Table of Hydraulic CNC Pendulum Shearing Machine):

| 设备型号 Equipment model | 可剪规格长*宽(mm) Specifications of the sheet metal that can be sheared | 剪切角(°) Shearing angle | 行程次数(n/min) Stroke frequency | 后挡料距离(mm) Stroke frequency | 电机功率(kw) Motor power | 外形尺寸(长*宽*高) Overall dimensions |

| HT12K-4*2500 | 4*2500 | 1.5° | 18 | 20-600 | 5.5 | 3040*1610*1650 |

| HT12K-4*3200 | 4*3200 | 1.5° | 14 | 20-600 | 7.5 | 3840*1610*1650 |

| HT12K-4*4000 | 4*4000 | 1.5° | 10 | 20-600 | 7.5 | 4640*1705*1700 |

| HT12K-4*5000 | 4*5000 | 1.5° | 10 | 20-600 | 7.5 | 5786*2200*2160 |

| HT12K-6*2500 | 6*2500 | 1.5° | 18 | 20-600 | 7.5 | 3040*1610*1650 |

| HT12K-6*3200 | 6*3200 | 1.5° | 14 | 20-600 | 7.5 | 3840*1610*1650 |

| HT12K-6*4000 | 6*4000 | 1.5° | 10 | 20-600 | 7.5 | 4640*1705*1700 |

| HT12K-6*5000 | 6*5000 | 1.5° | 10 | 20-750 | 11 | 5786*2200*2160 |

| HT12K-6*6000 | 6*6000 | 1.5° | 7 | 20-800 | 15 | 6900*2570*2280 |

| HT12K-8*2500 | 8*2500 | 1.5° | 14 | 20-600 | 7.5 | 3040*1610*1650 |

| HT12K-8*3200 | 8*3200 | 1.5° | 10 | 20-600 | 7.5 | 3840*1610*1650 |

| HT12K-8*4000 | 8*4000 | 1.5° | 8 | 20-600 | 7.5 | 4680*1705*1700 |

| HT12K-8*5000 | 8*500 | 1.5° | 7 | 20-750 | 11 | 5786*2252*2310 |

| HT12K-8*6000 | 8*6000 | 1.5° | 5 | 20-750 | 15 | 6900*2570*2280 |

| HT12K-10*2500 | 10*2500 | 1.5° | 11 | 20-800 | 11 | 3350*2050*1950 |

| HT12K-10*3200 | 10*3200 | 1.5° | 10 | 20-600 | 11 | 4050*2050*1950 |

| HT12K-10*4000 | 10*4000 | 1.5° | 12 | 20-800 | 15 | 4800*2200*2100 |

| HT12K-12*2500 | 12*2500 | 1.5° | 11 | 20-600 | 18.5 | 3350*2050*1950 |

| HT12K-12*3200 | 12*3200 | 1.5° | 10 | 20-800 | 18.5 | 4020*2050*2230 |

| HT12K-12*4000 | 12*4000 | 1.5° | 8 | 20-800 | 18.5 | 4820*2400*2730 |

| HT12K-16*2500 | 16*2500 | 2° | 8 | 20-800 | 18.5 | 3520*2060*2350 |

| HT12K-16*3200 | 16*3200 | 2° | 7 | 20-800 | 18.5 | 4062*2300*2320 |

| HT12K-16*4000 | 16*4000 | 2° | 5 | 20-800 | 22 | 4850*2350*2300 |

| HT12K-20*2500 | 20*2500 | 2° | 6 | 20-800 | 22 | 3440*2088*2570 |

| HT12K-20*3200 | 20*3200 | 2° | 5 | 30-800 | 37 | 4150*235*2710 |

| HT12K-20*4000 | 20*4000 | 2° | 5 | 30-1000 | 37 | 4280*2400*2730 |

| HT12K-20*5000 | 20*5000 | 3° | 4 | 20-800 | 37 | 5900*3000*3300 |

| HT12K-25*2500 | 25*2500 | 3° | 5 | 40-800 | 37 | 3500*2400*2500 |

| HT12K-25*3200 | 25*3200 | 3° | 4 | 40-1000 | 37 | 4200*2400*2500 |