服务热线

13905146213

数控闸式剪板机的工作原理是通过数控系统控制各个部件协同工作,实现对板材的精确剪切。以下是其具体工作原理:

数控系统控制:操作人员在E21S或DAC-360T数控系统的操作界面上输入剪切参数,如板材厚度、长度、剪切角度等。E21S或DAC-360T数控系统根据这些输入的参数,精确计算出剪切过程中各个动作的执行顺序和时间,然后向各个部件的驱动装置发送指令。 送料装置:送料装置通常由伺服电机、传动机构和滚轮等组成。接收到E21S或DAC-360T数控系统的指令后,伺服电机驱动传动机构,带动滚轮转动,从而将板材按照设定的速度和长度准确地输送到剪切位置。本设备配备了先进的自动定位装置,能够快速准确地将板材定位到剪切起始位置,提高了剪切精度和效率。 刀具系统:刀具系统是剪板机的核心部件,由上刀片和下刀片组成。上刀片安装在滑块上,滑块通过液压或机械驱动装置实现上下运动。下刀片固定在工作台上,与上刀片配合完成剪切动作。当板材输送到指定位置后,数控系统发出信号,驱动装置推动滑块向下运动,使上刀片与下刀片闭合,利用刀片的锋利刃口对板材进行剪切。刀片的材质通常为高强度合金钢,经过特殊的热处理工艺,具有良好的耐磨性和韧性,能够保证在长时间的剪切工作中保持锋利,从而保证剪切质量。 压料装置:在剪切过程中,为了防止板材在剪切力的作用下发生移动或翘起,影响剪切精度,剪板机配备了压料装置。压料装置一般位于刀具的前方,由压料缸和压料板组成。在剪切前,压料缸驱动压料板向下运动,将板材紧紧压在工作台上,确保板材在剪切过程中保持稳定。 回程装置:完成一次剪切动作后,驱动装置带动滑块向上回程,回到初始位置,准备下一次剪切。同时,送料装置根据设定的参数,继续输送板材,进入下一个剪切循环。 通过数控系统对送料、刀具、压料等各个装置的精确控制,数控闸式剪板机能够实现对不同厚度、长度和材质的板材进行高效、精确的剪切加工,广泛应用于机械制造、汽车工业、电子设备等多个领域。

一、HT11K-E21S或DAC-360T系列数控液压闸式剪板机特点:

性能特点

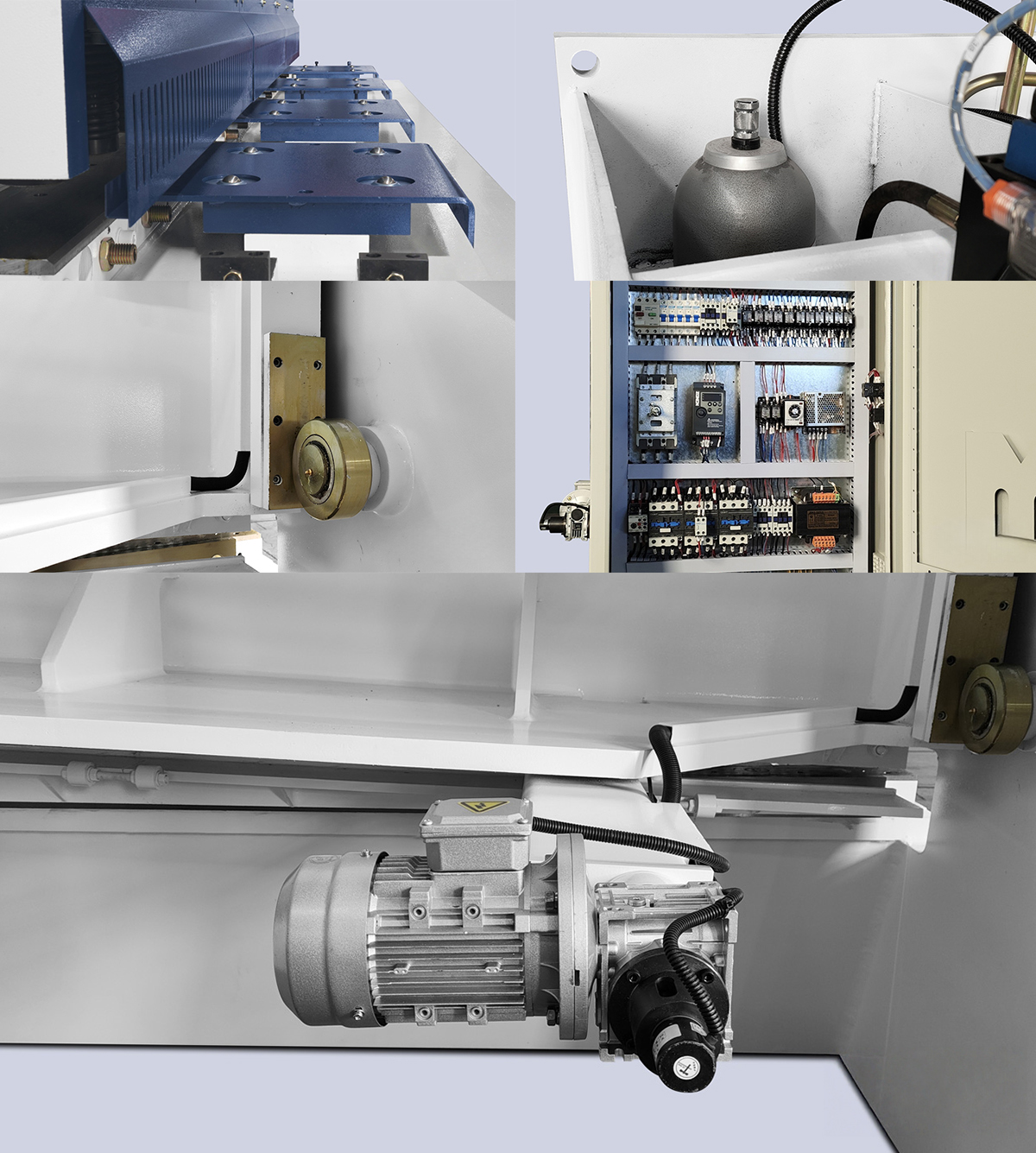

1、采用全钢板焊接结构,振动消除应力,具有很好的刚性与稳定性。

2、采用滚珠丝杆和直线导轨,伺服控制,定位精度高。

3、串联油缸使机床在剪切时,剪切角不会变动。

4、蓄能器回程平稳,迅速。

5、刀片间隙自动调整,准确、迅速、方便。

6、剪切角可调,减少板料扭曲变形。

7、电动后挡料、位置显示器,方便又准确。

8、滚轴式工作台,减少板料划伤,并可减少摩擦力。

9、本设备采用E21S或DAC-360T数控系统。

设备主要组件:

1)液压回路:上海高压泵有限公司

2)电器元件:欧姆龙电器

3)按键:欧姆龙电器

4)油泵:优质品牌的内啮合齿轮泵

5)变压器:欧姆龙

6)油缸:裕华 镍铬合金气缸

7)电气继电器:正泰集团股份有限公司/欧姆龙电器

| 设备型号 Equipment model | 可剪规格长*宽(mm) Specifications of the sheet metal that can be sheared | 剪切角(°) Shearing angle | 行程次数(n/min) Stroke frequency | 后挡料距离(mm) Distance of the rear stop gauge | 电机功率(kw) Motor power | 外形尺寸(mm)(长*宽*高) Overall dimensions |

| HT11K-4*2500 | 4*2500 | 1.5° | 18 | 20-600 | 5.5 | 3040*1610*1650 |

| HT11K-4*3200 | 4*3200 | 1.5° | 14 | 20-600 | 7.5 | 3840*1610*1650 |

| HT11K-4*4000 | 4*4000 | 1.5° | 10 | 20-600 | 7.5 | 4640*1705*1700 |

| HT11K-4*5000 | 4*5000 | 1.5° | 10 | 20-600 | 7.5 | 5786*2200*2160 |

| HT11K-6*2500 | 6*2500 | 1.5° | 18 | 20-600 | 7.5 | 3040*1610*1650 |

| HT11K-6*3200 | 6*3200 | 1.5° | 14 | 20-600 | 7.5 | 3840*1610*1650 |

| HT11K-6*4000 | 6*4000 | 1.5° | 10 | 20-600 | 7.5 | 4640*1705*1700 |

| HT11K-6*5000 | 6*5000 | 1.5° | 10 | 20-750 | 11 | 5786*2200*2160 |

| HT11K-6*6000 | 6*6000 | 1.5° | 7 | 20-800 | 15 | 6900*2570*2280 |

| HT11K-8*2500 | 8*2500 | 1.5° | 14 | 20-600 | 7.5 | 3040*1610*1650 |

| HT11K-8*3200 | 8*3200 | 1.5° | 10 | 20-600 | 7.5 | 3840*1610*1650 |

| HT11K-8*4000 | 8*4000 | 1.5° | 8 | 20-600 | 7.5 | 4680*1705*1700 |

| HT11K-8*5000 | 8*500 | 1.5° | 7 | 20-750 | 11 | 5786*2252*2310 |

| HT11K-8*6000 | 8*6000 | 1.5° | 5 | 20-750 | 15 | 6900*2570*2280 |

| HT11K-10*2500 | 10*2500 | 1.5° | 11 | 20-800 | 11 | 3350*2050*1950 |

| HT11K-10*3200 | 10*3200 | 1.5° | 10 | 20-600 | 11 | 4050*2050*1950 |

| HT11K-10*4000 | 10*4000 | 1.5° | 12 | 20-800 | 15 | 4800*2200*2100 |

| HT11K-12*2500 | 12*2500 | 1.5° | 11 | 20-600 | 18.5 | 3350*2050*1950 |

| HT11K-12*3200 | 12*3200 | 1.5° | 10 | 20-800 | 18.5 | 4020*2050*2230 |

| HT11K-12*4000 | 12*4000 | 1.5° | 8 | 20-800 | 18.5 | 4820*2400*2730 |

| HT11K-16*2500 | 16*2500 | 2° | 8 | 20-800 | 18.5 | 3520*2060*2350 |

| HT11K-16*3200 | 16*3200 | 2° | 7 | 20-800 | 18.5 | 4062*2300*2320 |

| HT12K-16*4000 | 16*4000 | 2° | 5 | 20-800 | 22 | 4850*2350*2300 |

| HT11K-20*2500 | 20*2500 | 2° | 6 | 20-800 | 22 | 3440*2088*2570 |

| HT11K-20*3200 | 20*3200 | 2° | 5 | 30-800 | 37 | 4150*235*2710 |

| HT11K-20*4000 | 20*4000 | 2° | 5 | 30-1000 | 37 | 4280*2400*2730 |

| HT11K-20*5000 | 20*5000 | 3° | 4 | 20-800 | 37 | 5900*3000*3300 |

| HT11K-25*2500 | 25*2500 | 3° | 5 | 40-800 | 37 | 3500*2400*2500 |

| HT11K-25*3200 | 25*3200 | 3° | 4 | 40-1000 | 37 | 4200*2400*2500 |

以上参数如有变动,恕不另行通知,本公司保留对此资料的最终解释权!