服务热线

13905146213

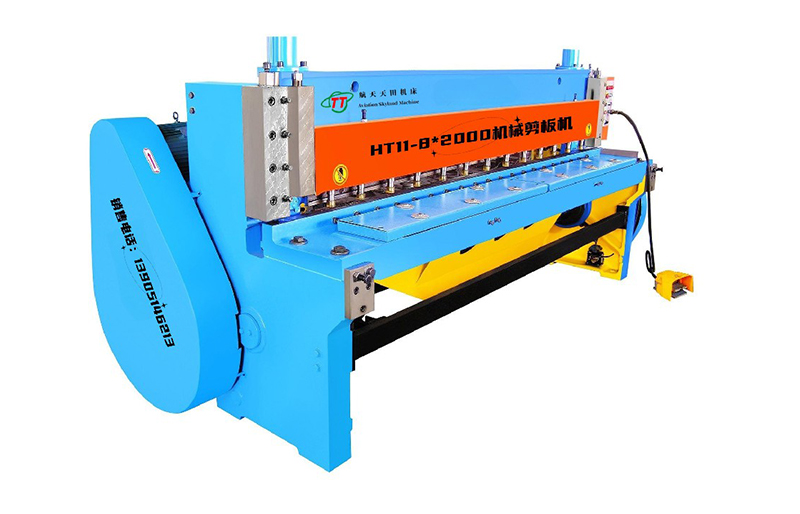

一、HT11系列小型机械剪板机技术参数(Technical Parameters of Series Small Mechanical Plate Shears):

| 型号 | 可剪板(mm) | 可剪板(mm) | 剪切(°) | 行程次数 | 后档料(mm) | 电机功率范(kw) |

| HT11-1x800 | 1 | 800 | 2°25′ | 20 | 350 | 1.5 |

| HT11-1x1000 | 1 | 1000 | 2°25′ | 20 | 350 | 1.5 |

| HT11-1x1300 | 1 | 1300 | 2°25′ | 20 | 350 | 1.5 |

| HT11-1x1500 | 1 | 1500 | 2°25′ | 20 | 350 | 2.2 |

| HT11-2x1000 | 2 | 1000 | 2°25′ | 20 | 350 | 2.2 |

| HT11-2x1300 | 2 | 1300 | 2°25′ | 20 | 350 | 2.2 |

| HT11-2x1500 | 2 | 1500 | 2°25′ | 20 | 350 | 3 |

| HT11-3x1300 | 3 | 1300 | 2°25′ | 20 | 350 | 3 |

| HT11-3x1500 | 3 | 1500 | 2°25′ | 20 | 350 | 3 |

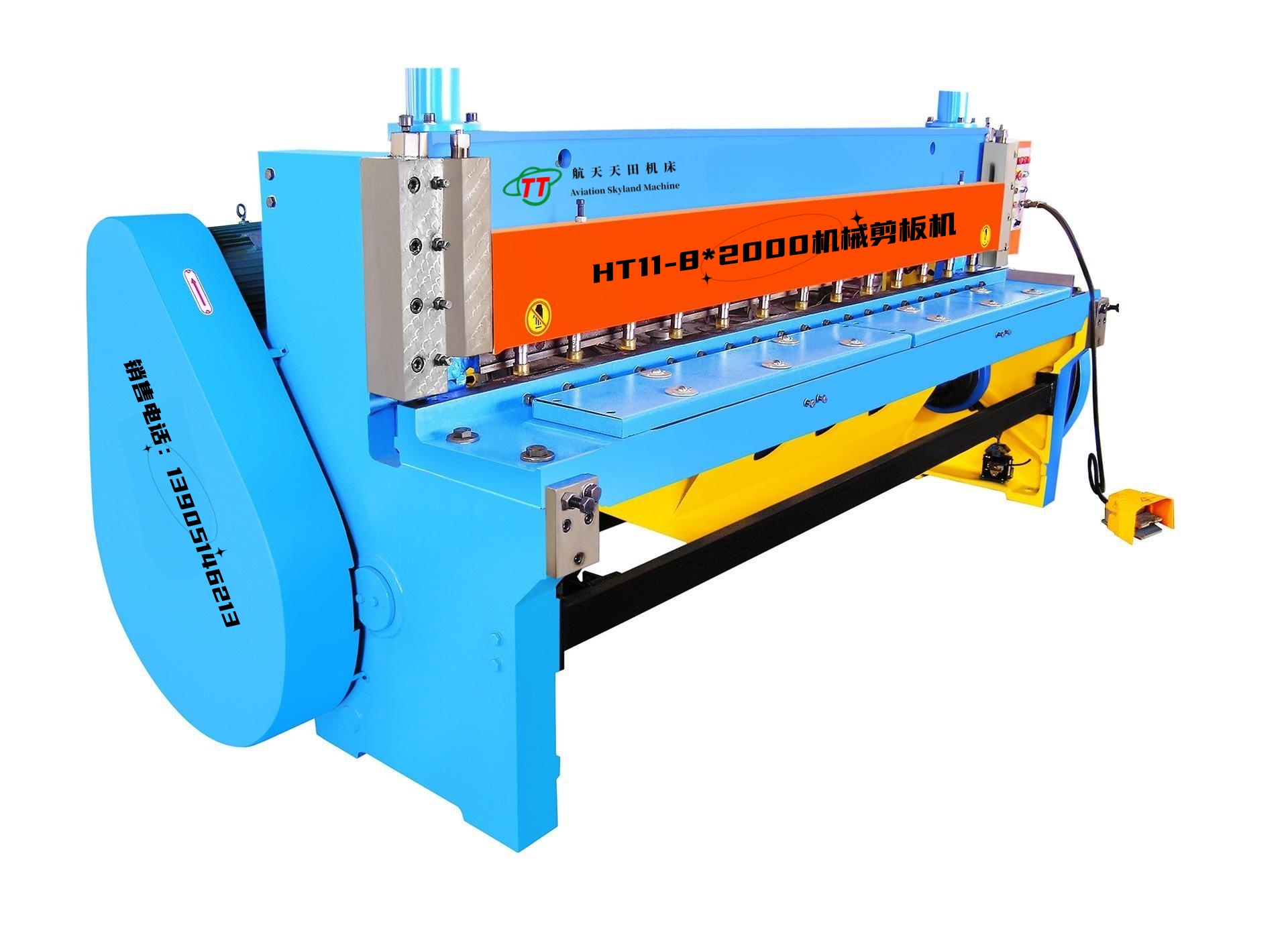

二、HT11系列机械剪板机技术参数表(Technical Parameter Table of Series Mechanical Plate Shears):

| 型号Type | HT11-4*2000 | HT11-4*2500 | HT11-6*2000 | HT11-6*2500 |

| 剪切厚度Shearing thichness | 4mm | 4mm | 6mm | 6mm |

| 剪切宽度Shearing width | 2000mm | 2500mm | 2000mm | 2500mm |

| 剪切角度Shearing angle | 1.5° | 1.5° | 2° | 2° |

| 行程次数Number stroke | 60 | 60 | 50 | 60 |

| 后挡料范围Back gang range | 0-680mm | 0-800mm | 10-580mm | 10-580mm |

| 电机功率Motor Power | 5.5Kw | 5.5Kw | 7.5Kw | 7.5Kw |

| 外形尺寸Dimensions | 3100*1590*1440 | 3510*1600*1465 | 3040*1550*1465 | 3510*1600*1465 |

备注:本资料所列数据为参考数据,如与机床实际数据不符,应以机床实际数据为准,

以上参数如有变动,恕不另行通知,本公司保留对此资料的最终解释权!