服务热线

13905146213

一、技术优势:

采用IPG光纤激光器或锐科光纤激光器和激光电源

IPG光纤激光器或锐科光纤激光器,模块化和冗余设计;体积小巧,重量轻,便于移动;易于集成,其性能稳定、产品整体质量得到安全保障。

二、光纤激光器的主要特点:

1、主要基本功能

1) 光纤激光器电-光转化效率高,转换效率达30%以上,可大幅度节约工作时的耗电,节省运行成本,达到较高的生产效率;

2) 激光器运行时仅仅需要电能,不需要产生激光的额外气体,具有较低的运行和维护费用;

3) 光纤激光器采用半导体模块化和冗余设计,谐振腔内无光学镜片,不需要启动时间,具有免调节、免维护、高稳定性的优点,降低了配件成本和维护的时间,这是传统激光器无法比拟的;

4) 光纤激光器的输出波长为1.06微米,是CO2波长的1/10,输出的光束质量好,功率密度高,有利于金属材料的吸收,具有卓越的切割、焊接能力,从而使加工的费用降低;

5) 整机光路由光纤传输,不需要复杂的反射镜等导光系统,光路简单,结构稳定,外光路免维护;

6) 光通过光纤导出,使机械系统的设计变得非常简单,非常容易与机器人或多维工作台集成;

7) 激光器加上光闸后可以一器多机,通过光纤分光,分成多路多台同时工作,易于扩展功能,升级方便、简单;

8) 光纤激光器体积小,重量轻,工作位置可移动,占地面积小;

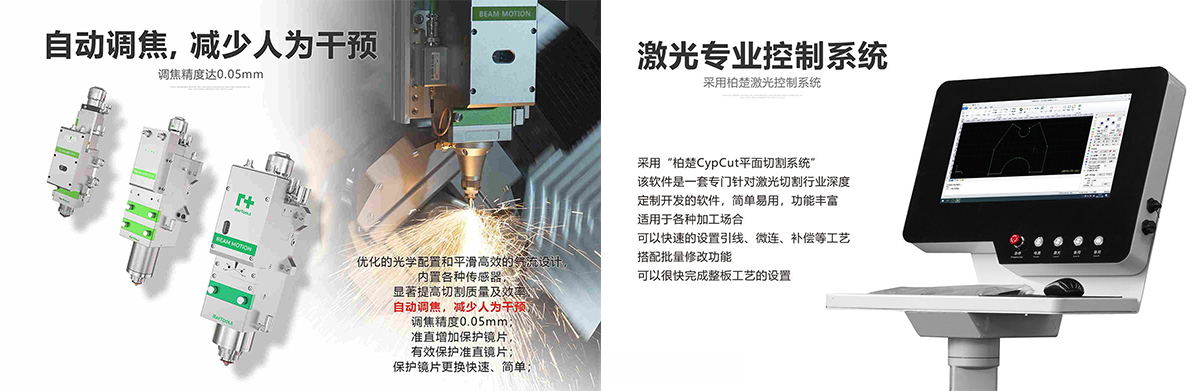

2、自动变焦激光头

1)焦点可自动调节,适用多种焦距;

2)电容式传感、全自动随动系统;

3)采用复合镜片、内置水冷结构;

4)准直和聚焦组件的双水冷恒温保证;

5)采用抽屉式镜座,更换保护镜片快速; 平滑高效气流设计;

6)适配各种光纤激光器;

7)短、长焦距通用,可实现薄或厚板良好的切割效果;

8)全部配备准直保护镜,更好的防护准直镜;

9)QBH圆周位置可调,保证每台QBH红点朝外,方便光纤头的插拔;

10)焦点位置可视窗口,确保输入焦点与输出焦点准确一致;

三、性能特点:

7、进口高精度电控比例阀,精确控制切割辅助气体的气压,以达精确的切割效果。

四、激光切割机的基本原理:

激光切割的特点:

1、切缝窄,变形小,精度高,速度快,效率高 。

3、相对于冲床,剪板机,它不需要模具,节约了换模具的时间,降低了加工成本。能切割复杂的图形。

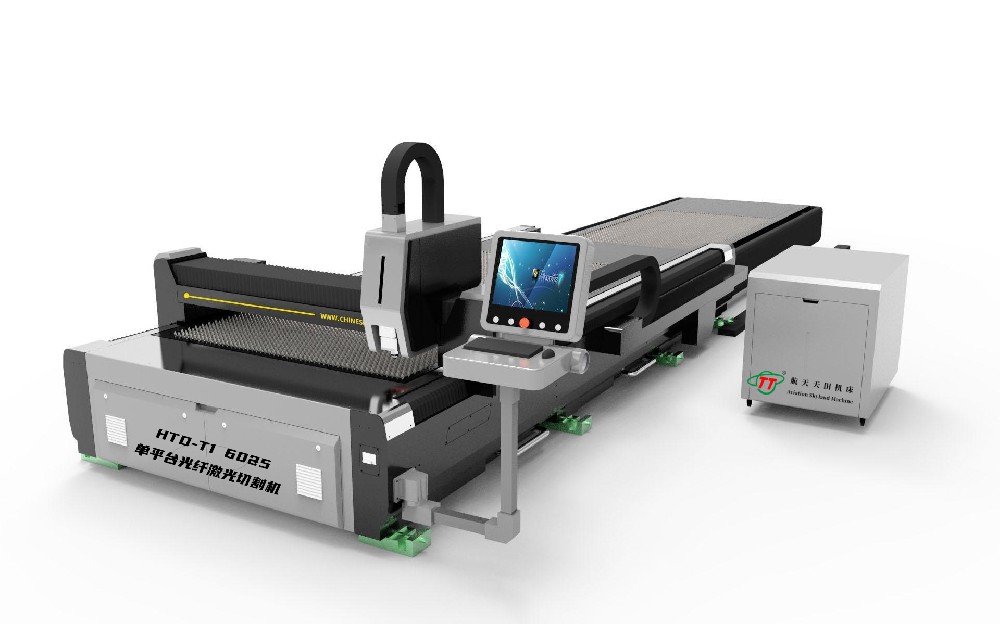

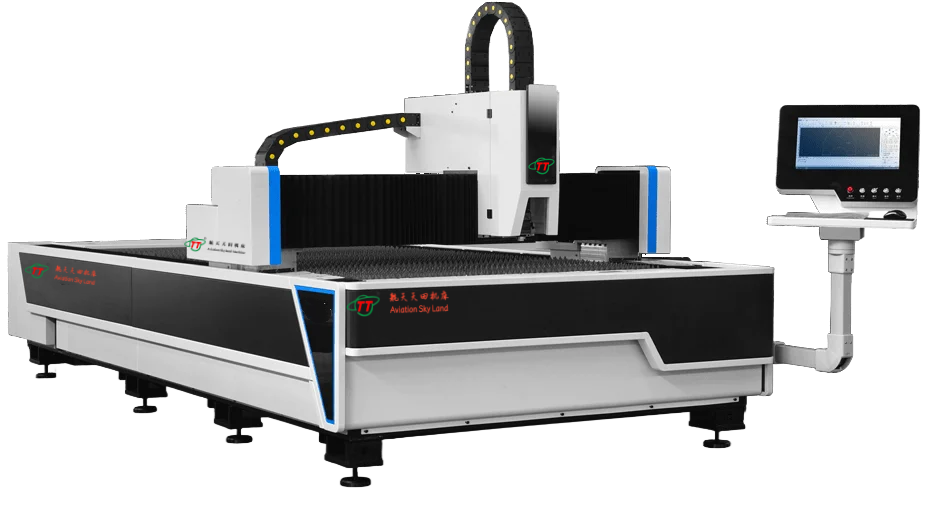

| 设备型号 Equipment Model | HTD-T1-3015 | HTD-T1-4015 | HTD-T1-4020 | HTD-T1-6015 | HTD-T1-6020 | HTD-T1-6025 |

| 加工范围长*宽 Processing Pipe Diameter (mm) | 3000*1500mm | 4000*1500mm | 4000*2000mm | 6000*1500mm | 6000*2000mm | 6000*2500mm |

| X轴行程 Travel of X-axis | 1505mm | 1505mm | 2010mm | 1505mm | 2010mm | 2510mm |

| Y轴行程 Travel of Y-axis | 3005mm | 4010mm | 4010mm | 6010mm | 6010mm | 6010mm |

| Z轴行程 Travel of Z-axis | 150mm | 150mm | 150mm | 150mm | 150mm | 150mm |

| X/Y定位精度 Positioning Accuracy of X/Y Axis | ±0.05mm | ±0.05mm | ±0.05mm | ±0.05mm | ±0.05mm | ±0.05mm |

| X/Y重复定位精度 Repeat Positioning Accuracy of X/Y Axis | ±0.03mm | ±0.03mm | ±0.03mm | ±0.03mm | ±0.03mm | ±0.03mm |

| X/Y最大加速度 Maximum Speed of X/Y Axis | 1.0-1.5G | 1.0-1.5G | 1.0-1.5G | 1.0-1.5G | 1.0-1.5G | 1.0-1.5G |

| 高度调节 Height Adjustment | 平面自动跟踪 (Automatic Planar Tracking) | 平面自动跟踪 (Automatic Planar Tracking) | 平面自动跟踪 (Automatic Planar Tracking) | 平面自动跟踪 (Automatic Planar Tracking) | 平面自动跟踪 (Automatic Planar Tracking) | 平面自动跟踪 (Automatic Planar Tracking) |

| 最小线宽 Minimum Line Width | 0.15mm | 0.15mm | 0.15mm | 0.15mm | 0.15mm | 0.15mm |

| 工作台最大载重 Maximum Load Capacity of the Workbench | ±0.03mm | ±0.03mm | ±0.03mm | ±0.03mm | ±0.03mm | ±0.03mm |

| 最大运行速度 Maximum Operating Speed | 600KG | 650KG | 650KG | 700KG | 700KG | 750KG |

| 传动系统 Transmission System | 龙门双驱 (Gantry - type Dual - drive) | 龙门双驱 (Gantry - type Dual - drive) | 龙门双驱 (Gantry - type Dual - drive) | 龙门双驱 (Gantry - type Dual - drive) | 龙门双驱 (Gantry - type Dual - drive) | 龙门双驱 (Gantry - type Dual - drive) |

| 数控系统 Numerical Control (NC) System | CypCut | CypCut | CypCut | CypCut | CypCut | CypCut |

| 激光器功率 Laser Power | 1000W-200000W | 1000W-200000W | 1000W-200000W | 1000W-200000W | 1000W-200000W | 1000W-200000W |

| 外形尺寸(长*宽*高)mm Overall Dimensions (Length × Width × Height) | 4700*2900*1800(mm) | 5600*2900*1800(mm) | 5600*3500*1800(mm) | 7700*2900*1800(mm) | 4700*3400*1800(mm) | 4700*3850*1800(mm) |

备注:本资料所列数据为参考数据,如与机床实际数据不符,应以机床实际数据为准,

以上参数如有变动,恕不另行通知,本公司保留对此资料的最终解释权!