HTD - GM 三维高精密数控光纤激光切割机凭借其高精度、高速度和多样化的切割能力,广泛应用于多个行业,主要应用于小尺寸高精度产品的加工;以下是一些主要的应用行业:

汽车制造行业:

零部件加工:用于切割汽车发动机、变速器等关键零部件的外壳、支架等,高精度的切割能保证零部件的尺寸精度和表面质量,提升汽车的整体性能。

车身结构件加工:切割汽车车身的车架、车门、车顶等部位的板材和管材,实现复杂形状的加工,满足车身轻量化和高强度的设计要求。

内饰件加工:切割汽车内饰的装饰板、仪表盘等部件,可进行精细的图案切割和个性化定制,提升内饰的美观度和品质。

航空航天行业:

航空发动机部件加工:切割航空发动机的叶片、燃烧室等关键部件,高精度的切割能够保证部件的尺寸精度和表面质量,满足航空发动机高转速、高温、高压的工作要求。

机身结构件加工:切割飞机机身的框架、蒙皮等结构件,可实现复杂曲面的加工,保证机身的强度和轻量化设计。

航空航天零部件的修复和改装:对于一些航空航天零部件的修复和改装,该激光切割机能够精确地切割和加工,保证修复和改装的质量。

机械制造行业:

模具加工:切割模具的模架、型腔等部件,高精度的切割能保证模具的尺寸精度和表面质量,提高模具的使用寿命和生产效率。

机械设备零部件加工:切割机械设备的齿轮、轴、箱体等零部件,可实现多种材料的切割,满足不同机械设备的加工需求。

通用零部件加工:加工各种通用零部件,如螺栓、螺母、垫片等,高精度的切割能保证零部件的尺寸精度和表面质量。

电气电子行业:

电气设备外壳加工:切割电气设备的外壳,如配电柜、控制柜等,可实现复杂形状的加工,保证外壳的精度和防护性能。

电子元器件加工:切割电子元器件的电路板、散热片等部件,高精度的切割能保证元器件的尺寸精度和表面质量,提升电子设备的性能和可靠性。

电池行业:用于切割电池的外壳、极片等部件,可实现高精度的切割,保证电池的安全性和性能。

五金制品行业:

五金工具加工:切割五金工具的刀片、钳子、扳手等部件,高精度的切割能保证工具的尺寸精度和表面质量,提高工具的使用寿命和使用性能。

建筑五金加工:切割建筑五金的门窗把手、合页、锁具等部件,可实现多种材料的切割,满足建筑五金的加工需求。

装饰五金加工:切割装饰五金的饰品、挂件等部件,可进行精细的图案切割和个性化定制,提升装饰五金的美观度和品质。

广告标识行业:

广告标牌制作:切割各种材质的广告标牌,如不锈钢标牌、铝合金标牌等,可实现复杂图案的切割和个性化定制,提升广告标牌的美观度和辨识度。

标识制作:切割标识的字体、图案等部件,可进行精细的切割和加工,保证标识的精度和质量。

展示道具制作:切割展示道具的框架、面板等部件,可实现多种材料的切割,满足展示道具的加工需求。

厨具卫浴行业:

医疗器械行业:

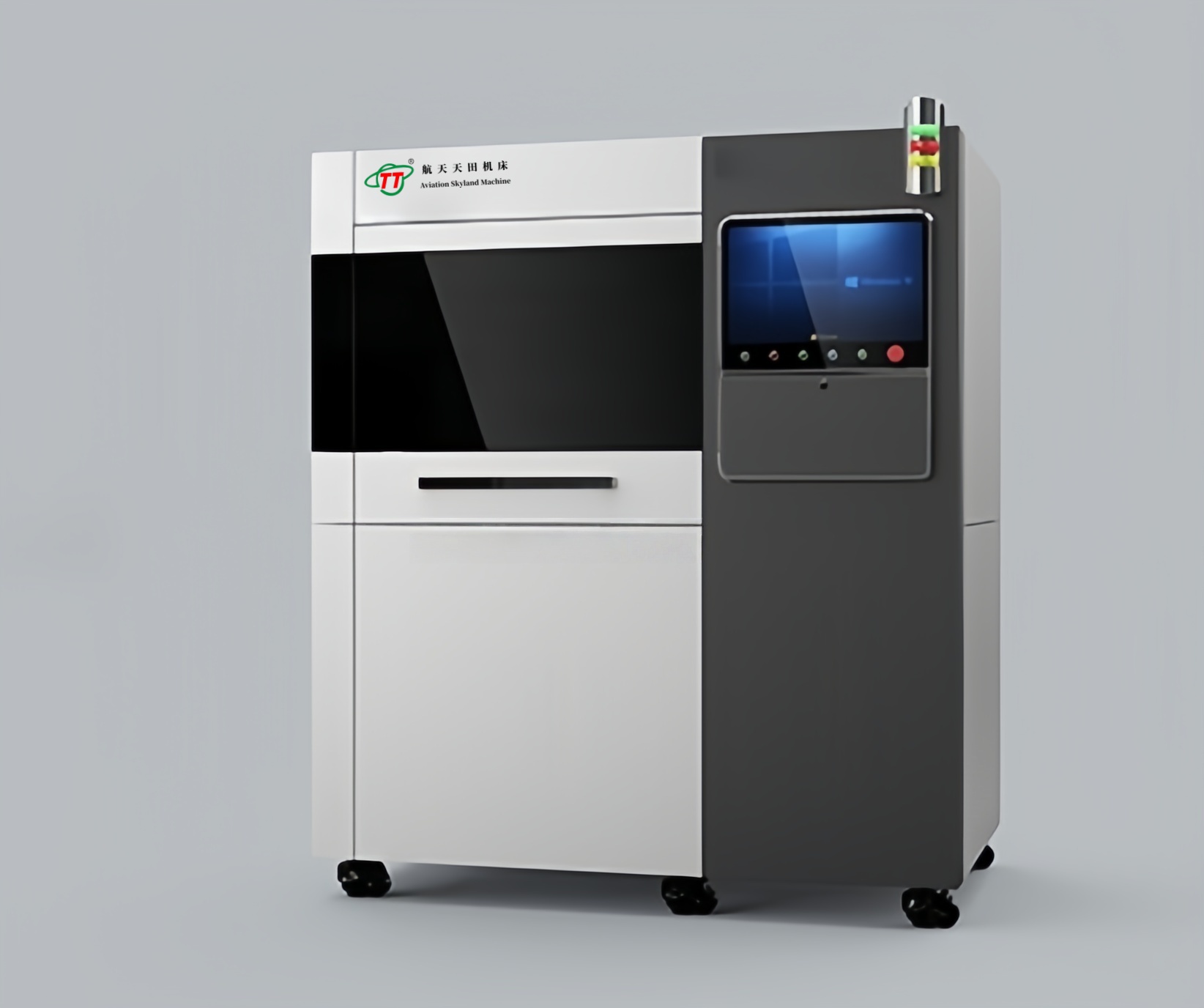

HTD - GM 三维高精密数控光纤激光切割机配置:

HTD - GM 三维高精密数控光纤激光切割机性能的介绍:

采用先进的柏楚4000+数控系统和高精度的传动部件,能够实现高精度的切割。其定位精度可达 ±0.05mm 甚至更高,确保切割的尺寸精度准确,对于一些需要高精度加工的零部件,如汽车零部件、航空航天部件等的加工,能够满足严格的精度要求。

配备高分辨率的电容式随动系统,检测精度可达 ±0.01mm,实时保持焦点与工件之间的距离在 ±0.1mm 范围内,即使是复杂曲面的工件,也能保证切割焦点始终处于最佳位置,从而保证切割质量的一致性。

具备自动上下料系统,如采用机器人或自动传输线等装置,实现了工件的自动上料、定位和下料,减少了人工操作,提高了生产效率和加工精度,同时也降低了操作人员的劳动强度。

支持 CAD/CAM 软件集成,能够直接导入三维 CAD 模型,自动生成切割路径,并进行路径优化和刀具补偿等操作,大大缩短了编程时间,提高了生产效率。此外,还具备远程监控功能,通过网络连接,操作人员可以在办公室或其他地方远程监控设备的运行状态、生产进度和故障信息等,实现了智能化的生产管理。

备注:本资料所列数据为参考数据,如与机床实际数据不符,应以机床实际数据为准,以上参数如有变动,恕不另行通知,本公司保留对此资料的最终解释权!