服务热线

13905146213

汽车制造领域:

车身结构件加工:用于切割汽车车身的各种管材,如车架纵梁、横梁、车门防撞梁等。能够精确切割管材的形状和尺寸,满足车身结构件的高精度要求,保证车身的强度和安全性。

汽车零部件制造:可切割汽车发动机的进气管、排气管、油管等零部件,以及汽车座椅骨架的管材。通过精确控制切割参数,实现对不同材质和壁厚管材的高质量切割,提高零部件的加工精度和生产效率。

航空航天领域:

航空发动机部件加工:可切割航空发动机的燃油管、液压管等管材,能够满足航空发动机对管材加工精度和表面质量的严格要求。通过高精度的切割和随动控制,保证管材的尺寸精度和切割质量,提高航空发动机的性能和可靠性。

飞机机身结构件制造:用于切割飞机机身的框架结构管材,如机翼、机身骨架等。能够根据飞机机身的设计要求,精确切割管材的形状和角度,实现复杂结构件的加工,提高飞机机身的强度和轻量化程度。

机械制造领域:

机械设备框架加工:可切割各种机械设备的框架管材,如工业机器人的手臂框架、自动化生产线的机架等。通过高精度的切割和伺服随动控制,保证框架结构的精度和稳定性,提高机械设备的性能和可靠性。

机械零部件加工:用于切割机械传动系统的管材,如传动轴、液压管等。能够精确控制切割尺寸和形状,满足机械零部件的高精度加工要求,提高机械零部件的质量和生产效率。

建筑装饰领域:

建筑幕墙加工:可切割建筑幕墙的管材,如铝合金型材、不锈钢管材等。能够根据建筑幕墙的设计要求,切割出各种形状和尺寸的管材,实现幕墙的多样化设计和安装。通过高精度的切割和随动控制,保证管材的切割精度和表面质量,提高建筑幕墙的美观度和安全性。

室内装饰管材加工:用于切割室内装饰的管材,如楼梯扶手、栏杆、装饰线条等。能够根据室内装饰的设计风格,切割出各种形状和图案的管材,实现个性化的装饰效果。通过高精度的切割和伺服随动控制,保证管材的切割精度和表面质量,提高室内装饰的品质和美观度。

家具制造领域:

家具框架加工:可切割家具框架的管材,如实木家具的框架、金属家具的管材等。能够根据家具的设计要求,切割出各种形状和尺寸的管材,实现家具框架的多样化设计和制造。通过高精度的切割和伺服随动控制,保证管材的切割精度和表面质量,提高家具的结构强度和美观度。

家具装饰管材加工:用于切割家具装饰的管材,如家具的装饰线条、拉手等。能够根据家具的装饰需求,切割出各种形状和图案的管材,实现个性化的装饰效果。通过高精度的切割和伺服随动控制,保证管材的切割精度和表面质量,提高家具的装饰品质和美观度。

石油化工领域:

管道加工:可切割石油化工行业的各种管道,如输油管道、输气管道、化工管道等。能够根据管道的设计要求,精确切割管材的长度、角度和形状,满足管道安装的高精度要求,保证管道的密封性和安全性。

设备零部件加工:用于切割石油化工设备的零部件管材,如反应釜的搅拌轴、换热器的管材等。通过高精度的切割和伺服随动控制,保证零部件的加工精度和表面质量,提高石油化工设备的性能和可靠性。

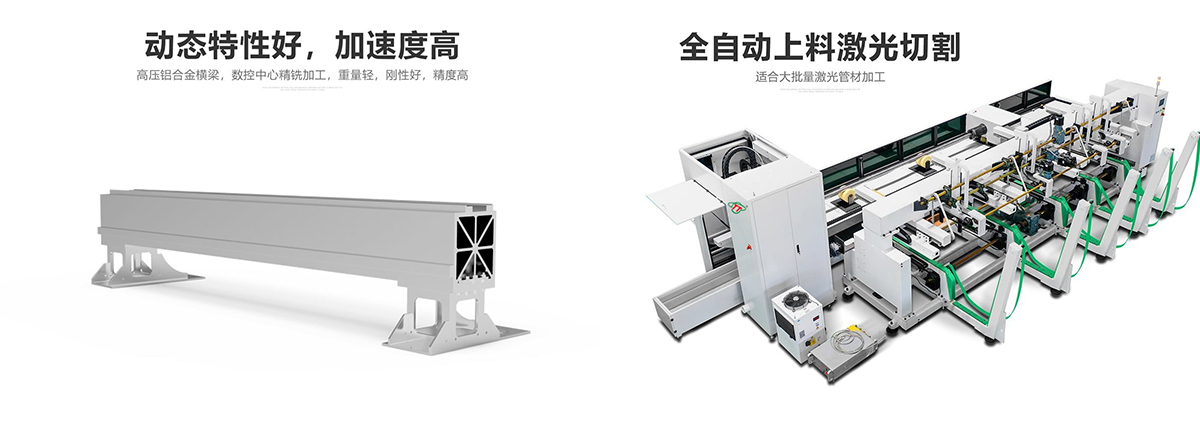

二、HT-TR伺服随动全自动上料数控光纤激光切管机的工作原理涉及上料、送料、激光切割等多个环节,以下是详细的工作原理介绍:

上料环节:设备配备专门的侧挂式上料机构,配备自动料架,将待加工的管材放置在特定的上料自动料架上区域,上料机构会自动识别管材的规格和形状,将管材抓取并放置到送料装置上。部分先进的上料系统还具备自动分拣功能,能够对不同材质、管径的管材进行分类上料,以满足多样化的加工需求。

伺服送料环节:送料系统由伺服电机驱动,通过滚珠丝杠、直线导轨等精密传动部件实现管材的精确输送。伺服电机能够根据数控系统的指令,精确控制管材的送料速度和长度。在送料过程中,伺服系统实时监测管材的位置和运动状态,确保送料的精度和稳定性。例如,当需要切割不同长度的管材时,伺服系统能够快速、准确地调整送料长度,误差可控制在极小范围内。

随动系统工作原理:随动系统是该设备的关键部分,主要用于跟踪管材的形状和位置变化。在切割过程中,管材可能会因材质、加工应力等因素发生微小的变形或位置偏移。随动系统通过传感器(如激光传感器、视觉传感器等)实时检测管材的实际位置和姿态,然后反馈给数控系统。数控系统根据反馈信息,通过伺服电机调整切割头的位置和角度,使切割头始终与管材表面保持合适的距离和角度,确保激光切割的精度和质量。

激光切割环节:数控系统根据预先编制的切割程序,控制光纤激光发生器产生高能量的激光束。激光束通过光纤传输到切割头,经聚焦透镜聚焦后,照射在管材表面。激光的高能量使管材表面的材料迅速熔化或汽化,同时,辅助气体(如氧气、氮气等)通过切割头喷出,将熔化或汽化的材料吹离切割区域,从而实现管材的切割。在切割过程中,数控系统还可以根据管材的材质和厚度,精确控制激光功率、切割速度、辅助气体压力等参数,以达到最佳的切割效果。

出料及余料处理:切割完成的管材通过出料装置被送出设备,出料装置可以对切割好的管材进行收集、整理和分类。对于切割剩余的废料或余料,设备配备的废料处理系统会进行收集和处理,例如通过废料输送带将废料输送到指定的废料收集区域,以保持工作环境的整洁和安全。

伺服随动全自动上料数控光纤激光切管机通过各系统的协同工作,实现了管材的高精度、高效率切割,广泛应用于机械制造、汽车、航空航天、建筑等行业。

三、HT-TR伺服随动全自动上料数控光纤激光切管机具有下列优点:

1.精度高,速度快。

2.切缝窄,切割面光滑,切割质量好。

3.无接触切割,切边受热影响很小,基本没有工件热变形,避免材料冲剪时形成的塌边,切缝一般不需要二次加工。

4.不损伤工件:激光切割头不与材料表面相接触,不划伤工件。

5.不受被切割材料的硬度影响:激光可以对钢板、不锈钢、铝合金板、硬质合金等进行加工,不管什么样的硬度,都可以进行无形切割。

6.不受工件形状的影响: 激光加工柔性好,可以加工任意图形,可以切割管材及其它异型材。

7.节约模具投资:激光加工不需模具,没有模具消耗,从而节省了加工费用,降低了生产成本,尤其适合大件产品的加工。

8.节省材料: 采用电脑编程,可以把不同形状的产品进行整张材料套裁,大限度地提高材料的利用率。

9.提高新产品开发速度:产品图纸形成后,马上可以进行激光加工,在短的时间内得到新产品的实物。

10.节能环保。

(3D工作视频)3D working video

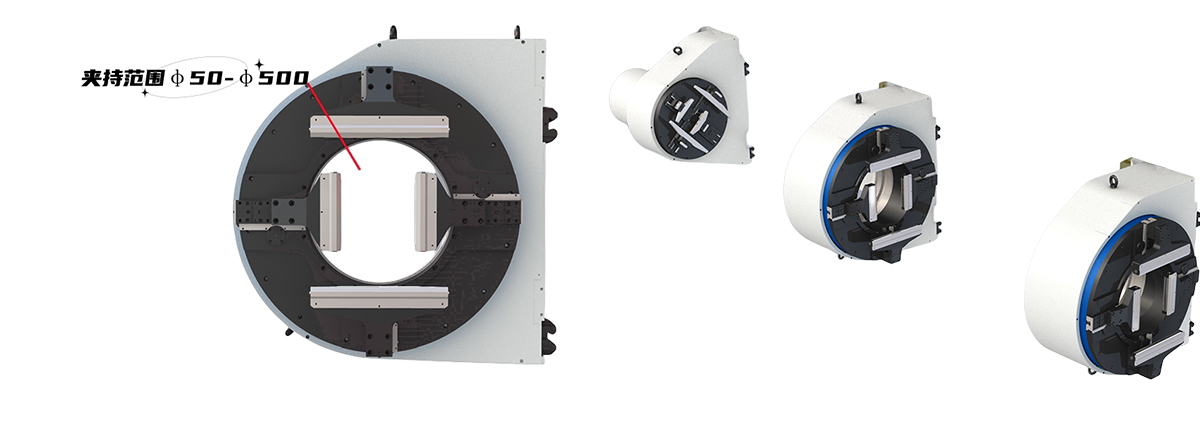

三卡盘结构 创新加工

三卡盘结构设计,加工过程采用三个卡盘夹持支撑,可对管材的弯曲、扭曲较大的管材调整夹持力进行矫正切割,可避免因管料后端抖动而影响前端切割精度,运行速度快、精度高、载重高。

负载大、范围大

激光切管机的三卡盘结构,可避免因管料高速旋转抖动而影响切割精度和效率。夹持范围大,高承载力卡盘,最大夹持范围可达500mm,最大承载可达2吨,更大填补重型管材切割需求,卡爪夹持力智能可调,夹持范围可根据管材范围快速更换。

五、激光器优点:

1、为用户节省成本。

2、切割6mm以下的金属板材只需要吹空气(普通空气0.6MPa-0.8MPa),而不需要氧气。节省使用氧气的费用。切割速度快于同类设备。

3、切割速度高于同类设备30%,切割速度达到每分钟4米。

4、重管多根上料 重载下料。

5、侧挂式导轨结构,防尘效果好;上料架型材上料,V型架接料,无需等待自动化程度高,质量最优。 对夹下料,可防止管材在运输和切割过程中滚动储料输送架,可存储多根管材,方便人员运输,节省时间。

伺服随动全自动上料数控光纤激光切管机特点说明:

1、本公司激光切割机采用先进国外进口IPG或Raycus(锐科)的激光器技术,光斑小,功率集中,割缝细、切割效率高,

2、采用柏楚4000+数控系统,采用优质先进的波刺黑金刚激光切割头。

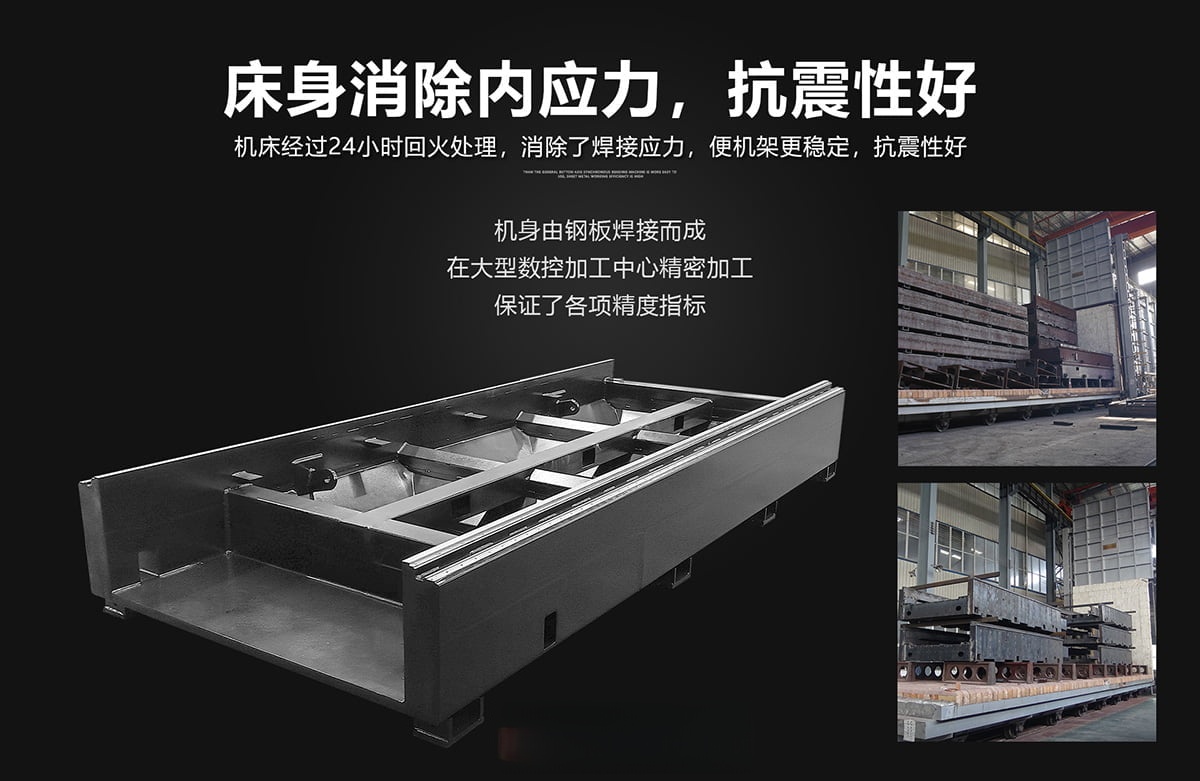

2.设备框架采用龙门双丝杠、双伺服电机同步驱动,运行平稳,切割精度高。这种方式只有数百万元的大功率激光切割机采用。切割细线条、小圆等细小图案,不变形,效果好。采用焦距跟随设计,即使材料表面不平整仍可保证切割质量切缝平整、美观,无需后序处理工序。

3.人性化设计的控制柜,方便用户操作使用。

六、伺服随动全自动上料数控光纤激光切管机技术参数:

| 型号 | HT-TR-12050 | HT-TR-9050 | HT-TR-12036 | HT-TR-9036 | HT-TR-L13050 |

| 加工范围 | φ50-508mm | φ50-508mm | φ50-360mm | φ50-360mm | φ50-508mm |

| □50-350mm | □50-350mm | □50-260mm | □50-260mm | □50-350mm | |

| 定位精度 | ±0.03mm/m | ±0.03mm/m | ±0.03mm/m | ±0.03mm/m | ±0.03mm/m |

| 重复定位精度 | ±0.05mm | ±0.05mm | ±0.05mm | ±0.05mm | ±0.05mm |

| 最大空运行速度 | 40m/min | 40m/min | 60m/min | 60m/min | 40m/min |

| 最大空转速度 | 50r/min | 50r/min | 80r/min | 80r/min | 50r/min |

| 单根管材最大质量 | 2000kg | 2000kg | 1200kg | 1200kg | 1500kg |

| 最大一次性下料尺寸 | 12000mm | 9000mm | 12000mm | 9000mm | 13000mm |

| 推荐功率段 | 1000W-80000W | ||||

备注:本资料所列数据为参考数据,如与机床实际数据不符,应以机床实际数据为准,

以上参数如有变动,恕不另行通知,本公司保留对此资料的最终解释权!