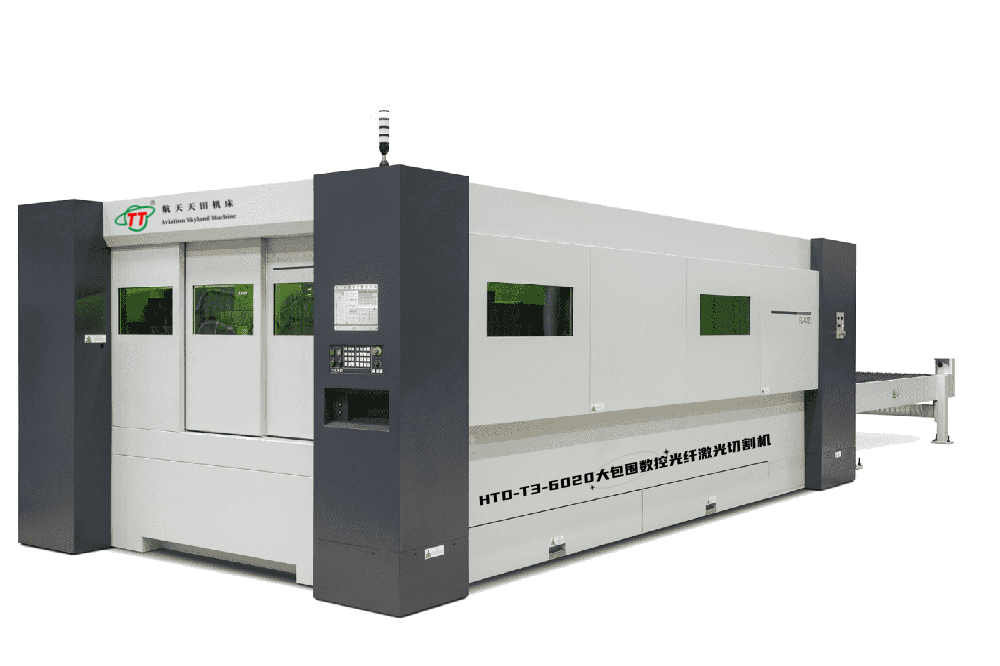

一、HTD-T3系列全封闭双交换台数控光纤激光切割机的工作原理及应用范围介绍:

工作原理:

上料与交换:设备配备双交换工作台,当一个工作台处于上料状态时,操作人员将待加工的板材放置在工作台上,并进行必要的固定和定位操作。另一个工作台则处于切割工作状态。当一个工作台完成上料后,通过交换机构快速将已上料的工作台与正在切割的工作台进行位置交换,保证切割工作的连续性。

激光发生与传输:数控系统控制光纤激光发生器产生高能量密度的激光束。激光束通过光纤传输至切割头,在切割头中,激光束被聚焦透镜聚焦,形成极小的光斑,从而在板材表面产生极高的能量密度。

切割过程:切割头根据数控系统生成的切割路径在板材上进行移动。辅助气体(如氧气、氮气等)通过切割头喷出,与激光作用下熔化或汽化的板材材料发生反应,将熔化或汽化的材料吹离切割区域,实现板材的切割。同时,数控系统精确控制切割头与板材表面的距离,确保切割质量。

切割参数控制:操作人员根据板材的材质、厚度等因素,在数控系统中设置合适的激光功率、切割速度、辅助气体压力等切割参数。数控系统根据这些参数精确控制激光发生器、切割头和辅助气体系统的工作,以达到最佳的切割效果。

***选配烟尘处理:全封闭结构配备高效的烟尘处理系统,在切割过程中,产生的烟尘和废气被收集并通过过滤装置进行净化处理,确保工作环境的清洁和操作人员的健康。

应用范围:

机械制造行业:用于切割各种机械零部件,如齿轮、法兰、支架等。可以切割不同形状和尺寸的零件,满足机械制造对高精度和高效率的要求。

汽车制造行业:可切割汽车车身结构件、零部件等,如车架纵梁、横梁、车门防撞梁、发动机零部件等。激光切割能够保证车身结构件的精度和质量,提高汽车的安全性和性能。

航空航天行业:适用于切割航空航天领域的高精度零部件,如飞机机身框架、发动机部件等。能够满足航空航天对材料加工精度和表面质量的严格要求。

电气设备制造行业:用于切割电气设备的外壳、电路板等部件。可以实现复杂图形的切割,满足电气设备对零部件加工精度和外观的要求。

厨具制造行业:可切割不锈钢等材质的厨具零部件,如锅具、水槽等。激光切割能够保证厨具的切割精度和表面质量,提高厨具的美观度和实用性。

广告标识制作行业:用于切割各种广告标识,如金属字、广告牌等。可以切割出各种复杂的图形和文字,满足广告标识制作对个性化和高精度的需求。

建筑装饰行业:可切割建筑装饰材料,如不锈钢装饰板、铝合金型材等。能够实现各种形状和图案的切割,为建筑装饰提供多样化的设计选择。

二、HTD-T3系列全封闭双交换台数控光纤激光切割机具有多方面优势,以下是详细介绍:

加工效率高:双交换台设计允许在一个工作台进行切割加工时,另一个工作台同步进行上下料操作。当一个工作台完成加工后,可快速切换到已准备好的另一个工作台继续切割,极大地减少了辅助时间,实现连续作业,大幅提高了整体加工效率。例如,在批量生产零件时,交换台的快速切换能使设备不停机地持续加工,有效缩短了生产周期。

安全性强:全封闭结构可有效防止激光对操作人员的伤害,同时能减少激光切割过程中产生的火花、烟雾及噪音对工作环境的影响。封闭式的设计还能避免外界因素干扰切割过程,保证切割质量稳定。比如,切割金属时产生的有害烟雾被封闭空间收集处理,减少了对车间空气质量的污染,保护了工人健康。

切割精度高:数控系统能精确控制激光头的运动轨迹和切割参数,实现高精度切割。全封闭环境可减少外界因素(如温度、湿度、灰尘等)对切割精度的影响,保证切割精度的一致性。即使长时间连续切割,也能保持较高的加工精度。例如,在切割精细的电子零件时,能达到极小的切割误差。

加工稳定性好:全封闭双交换台数控光纤激光切割机配备先进的冷却系统、稳定的光路系统和高精度的传动机构。这些组件协同工作,确保设备在长时间运行过程中保持稳定性能,减少故障发生概率。例如,冷却系统能及时带走激光发生器和切割头产生的热量,保证设备正常运行。

操作简便:通常配备人性化的操作界面,操作人员可通过数控系统方便地设置切割参数、导入切割图形等。设备的自动化程度高,降低了对操作人员的技能要求,提高了操作的便捷性和效率。例如,新员工经过简单培训就能快速上手操作设备。

材料适应性广:可以切割多种金属材料,如不锈钢、碳钢、铝合金、铜等,还能切割不同厚度的板材,满足不同行业的加工需求。无论是薄板的精细切割还是厚板的高效切割,都能取得良好的切割效果。比如,在汽车制造行业可切割车身结构件,在厨具生产中可切割不锈钢板材。

环保节能:相比传统切割方式,光纤激光切割能量利用率高,减少了能源消耗。全封闭结构配合有效的烟雾处理系统,能对切割过程中产生的烟雾和废料进行收集处理,减少环境污染,符合环保要求。例如,烟雾处理系统可过滤烟雾中的有害物质,使排放达到环保标准

三、HTD-T3系列全封闭双交换台数控光纤激光切割机所配光纤激光器的特点

1、卓越的光束质量:聚焦光斑更小,切割线条更精细,工作效率更高,加工质量更好;

2、较高的切割速度:是同等功率CO2激光切割机的2倍;

3、较高的稳定性:采用IPG光纤激光器或锐科光纤激光器,性能稳定,关键部件使用寿命可达10万小时;

4、较高的电光转换效率:光纤激光切割机比CO2激光切割机电光转换效率高3倍,节能环保;

5、较低的使用成本:整机耗电量仅为同类CO2激光切割机的20-30%;

6、较低的维护成本:无激光器工作气体;光纤传输,无需反射镜片;可节约大量维护成本;

7、产品操作维护方便:光纤传输,无需调整光路;

8、强的柔性导光效果:体积小巧,结构紧凑,易于柔性加工要求。

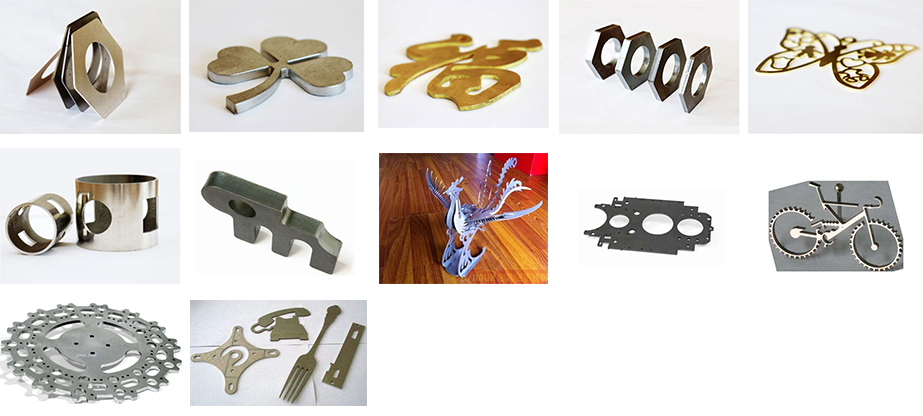

四、 HTD-T3系列全封闭双交换台数控光纤激光切割机样品效果图(Sample effect diagram of the HTD-T3 series fully enclosed double-exchange table CNC fiber laser cutting machine):

五、HTD-T3系列全封闭双交换台数控光纤激光切割机技术优势:

1、采用IPG光纤激光器或锐科光纤激光器和激光电源

IPG光纤激光器或锐科光纤激光器,模块化和冗余设计;体积小巧,重量轻,便于移动;易于集成,其性能稳定、产品整体质量得到安全保障。

(图片仅供参考,以实物为准 The picture is for reference only. The actual product shall prevail.)

2、 光纤激光器的主要特点

1) 光纤激光器电-光转化效率高,转换效率达30%以上,可大幅度节约工作时的耗电,节省运行成本,达到较高的生产效率;

2) 激光器运行时仅仅需要电能,不需要产生激光的额外气体,具有较低的运行和维护费用;

3) 光纤激光器采用半导体模块化和冗余设计,谐振腔内无光学镜片,不需要启动时间,具有免调节、免维护、高稳定性的优点,降低了配件成本和维护的时间,这是 传统激光器无法比拟的;

4) 光纤激光器的输出波长为1.06微米,是CO2波长的1/10,输出的光束质量好,功率密度高,有利于金属材料的吸收,具有卓越的切割、焊接能力,使加工的费用降低;

5) 整机光路由光纤传输,不需要复杂的反射镜等导光系统,光路简单,结构稳定,外光路免维护;

6) 光通过光纤导出,使机械系统的设计变得非常简单,非常容易与机器人或多维工作台集成;

7) 激光器加上光闸后可以一器多机,通过光纤分光,分成多路多台同时工作,易于扩展功能,升级方便、简单;

8) 光纤激光器体积小,重量轻,工作位置可移动,占地面积小;

3、采用自动变焦激光头

1)焦点可自动调节,适用多种焦距;

2)电容式传感、全自动随动系统;

3)采用复合镜片、内置水冷结构;

4)准直和聚焦组件的双水冷恒温保证;

5)采用抽屉式镜座,更换保护镜片快速; 平滑高效气流设计;

6)适配各种光纤激光器;

7)短、长焦距通用,可实现薄或厚板良好的切割效果;

8)全部配备准直保护镜,更好的防护准直镜;

9)QBH圆周位置可调,保证每台QBH红点朝外,方便光纤头的插拔;焦点位置可视窗口,确保输入焦点与输出焦点准确一致;

六、HTD-T3系列全封闭双交换台数控光纤激光切割机技术参数表:

| 设备型号 | HTD-T3-3015 | HTD-T3-4015 | HTD-T3-4020 | HTD-T3-6015 | HTD-T3-6020 | HTD-T3-6025 |

| 加工范围长*宽 | 3000*1500mm | 4000*1500mm | 4000*2000mm | 6000*1500mm | 6000*2000mm | 6000*2500mm |

| X轴行程 | 1505mm | 1505mm | 2010mm | 1505mm | 2010mm | 2510mm |

| Y轴行程 | 3010mm | 4010mm | 4010mm | 6010mm | 6010mm | 6100mm |

| Z轴行程 | 300mm | 300mm | 300mm | 300mm | 300mm | 300mm |

| X/Y定位精度 | ±0.05mm | ±0.05mm | ±0.05mm | ±0.05mm | ±0.05mm | ±0.05mm |

| X/Y重复定位精度 | ±0.03mm | ±0.03mm | ±0.03mm | ±0.03mm | ±0.03mm | ±0.03mm |

| X/Y最大加速度 | 1.0-1.5G | 1.0-1.5G | 1.0-1.5G | 1.0-1.5G | 1.0-1.5G | 1.0-1.5G |

| 高度调节 | 平面自动跟踪 | 平面自动跟踪 | 平面自动跟踪 | 平面自动跟踪 | 平面自动跟踪 | 平面自动跟踪 |

| 最小线宽 | 0.15mm | 0.15mm | 0.15mm | 0.15mm | 0.15mm | 0.15mm |

| 工作台最大载重 | ±0.03mm | ±0.03mm | ±0.03mm | ±0.03mm | ±0.03mm | ±0.03mm |

| 最大运行速度 | 600KG | 650KG | 650KG | 700KG | 700KG | 750KG |

| 传动系统 | 龙门双驱 | 龙门双驱 | 龙门双驱 | 龙门双驱 | 龙门双驱 | 龙门双驱 |

| 数控系统 | CypCut | CypCut | CypCut | CypCut | CypCut | CypCut |

| 激光器功率 | 1000W-30000W | 1000W-30000W | 1000W-30000W | 1000W-30000W | 1000W-30000W | 1000W-30000W |

| 外形尺寸(长*宽*高) | 8500*3300*2200(mm) | 11600*3300*2200(mm) | 11600*3800*12200(mm) | 14700*3300*2300(mm) | 14700*3800*2300(mm) | 14700*420*2300(mm) |

备注:本资料所列数据为参考数据,如与机床实际数据不符,应以机床实际数据为准,

以上参数如有变动,恕不另行通知,本公司保留对此资料的最终解释权!