服务热线

13905146213

一、激光手持焊是一种利用激光束进行焊接的技术,其工作原理如下:

激光产生

激光手持焊设备中的激光发生器通过激励源(如脉冲氙灯、半导体激光器等)向增益介质(如钕玻璃、YAG晶体、光纤等)输入能量,使增益介质中的粒子实现能级跃迁,形成粒子数反转分布,从而产生受激辐射,输出高能量密度、高方向性、单色性好的激光束。

激光传输

产生的激光束通过光纤等传输介质传导至手持焊接头。光纤具有良好的柔韧性和低损耗特性,可将激光高效地传输到焊接部位,同时方便操作人员灵活移动手持焊接头进行焊接作业。

激光聚焦与作用。

在手持焊接头中,激光束通过聚焦透镜等光学元件进行聚焦,使激光束在焊件表面形成一个极小的光斑,从而提高激光的能量密度。当聚焦后的激光束照射到焊件表面时,激光的能量被焊件材料吸收,使焊件表面迅速熔化甚至汽化,形成一个匙孔。随着激光束沿着焊接方向移动,匙孔也随之移动,周围的液态金属会不断填充匙孔后方的空间,冷却凝固后就形成了焊缝,从而实现焊接连接。

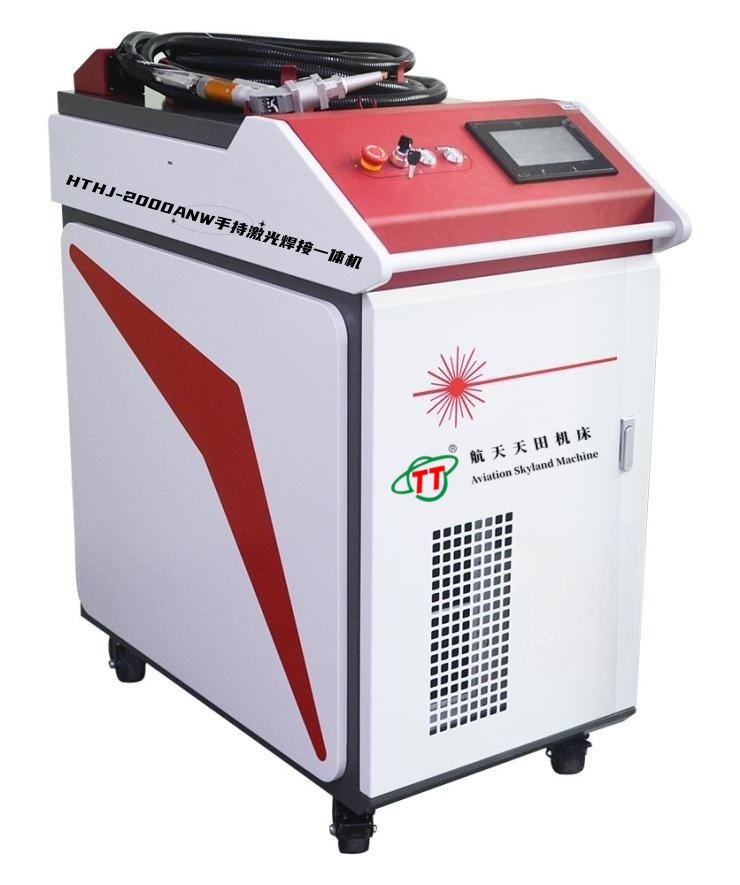

二、HTHJ--系列手持激光手持焊机机器的用途

手持激光焊机广泛应用于钣金加工、轨道交通、汽车、工程机械、农林机械、电气制造、电梯制造、家用电器、粮食机械、纺织机械、工具加工、石油机械、食品机械、厨具卫浴、装饰广告、激光对外加工服务。

手持激光焊机操作简单,无需专业焊接技术经验,简单培训2小时即可开始操作。焊接速度超快。一台手持式激光焊机基本可以替代3-5台普通焊机的输出。手持激光焊机焊接基本上可以不用耗材,节约生产成本。焊接之后,焊缝光亮、白皙,基本无需打磨即可。具有能量集中、热反射范围小、产品不易变形等优点。激光焊机能量集中,焊接强度很高。

三、HTHJ--系列手持激光焊接机机器常用规格(Common Specifications of HTHJ-series Handheld Laser Welding Machines):

| 设备名称 | 激光手持焊接一体机 |

|---|---|

| 型号 | HTHJ - 1000, HTHJ - 1500, HTHJ - 2000,HTHJ - 3000, HTHJ - 6000 |

| 常用功率 | 1000W、1500W、2000W 3000W 6000W |

| 激光类型 | 光纤激光 |

| 焊接材质 | 不锈钢、碳钢、铝合金等 |

| 焊接厚度 | 碳钢 / 不锈钢:0.5 - 3mm(1000W);0.5 - 5mm(1500W);0.5 - 8mm(2000W) 铝合金:0.5 - 2mm(1000W);0.5 - 3mm(1500W);0.5 - 5mm(2000W) |

| 焊接速度 | 0 - 8m/min(具体取决于材料厚度及材质) |

| 工作模式 | 连续焊、脉冲焊 |

| 外形尺寸(主机) | 约 1200mm×800mm×1500mm(长 × 宽 × 高) |

| 外形尺寸(手持焊枪) | 约 350mm×80mm×200mm(长 × 宽 × 高) |

| 整机重量 | 主机约 180kg,手持焊枪约 3kg |

| 电源要求 | AC 380V±10%,50/60Hz |

| 冷却方式 | 水冷(内置高效水循环冷却系统) |

| 防护等级 | IP54 |

| 控制方式 | 触摸屏控制,操作简单直观 |

| 适用场景 | 五金加工、厨具制造、广告标牌、家具制造、汽车配件等行业。 |

备注:本资料所列数据为参考数据,如与机床实际数据不符,应以机床实际数据为准,

以上参数如有变动,恕不另行通知,本公司保留对此资料的最终解释权!