服务热线

13905146213

HTB -DA53T 系列电液伺服数控折弯机是一种具有高精度、高效率的金属加工设备,以下是其相关介绍

数控系统:采用荷兰 DeLem-DA53T 数控系统,也可选用瑞士 CYBELEC12 系统。这些系统具有先进的技术,如 Delem 二维图形编程设计工具,方便进行数控编程,可自动计算所有轴位置,一键生成数控程序,提高生产效率。系统还具备液压工序指定功能,能减少机器调整和测试工作。此外,彩色 TFT 显示和时尚的用户界面清晰,操作便捷,USB 接口可快速备份产品和模具,DA-0ffine 为离线编程提供解决方案。

结构设计:

整机采用钢板焊接结构,并经整体振动处理,一次装夹整体加工,保障了机身的刚性和加工精度。

人性化吊臂设计,基于实时的 Windows 操作系统,搭配三维彩色图形折弯机数控系统,为使用者提供友好操作界面。

轴控制:标准为数控 4+1 轴,即 Y1、Y2、X、R+V 轴。其中,Y1、Y2 轴用于控制滑块两侧油缸,X 轴为后挡料的水平移动轴,R 轴用于控制后挡料的旋转,V 轴为工作台的挠度补偿轴。可根据用户需要,将后定位控制扩展到六轴。

精度保障:

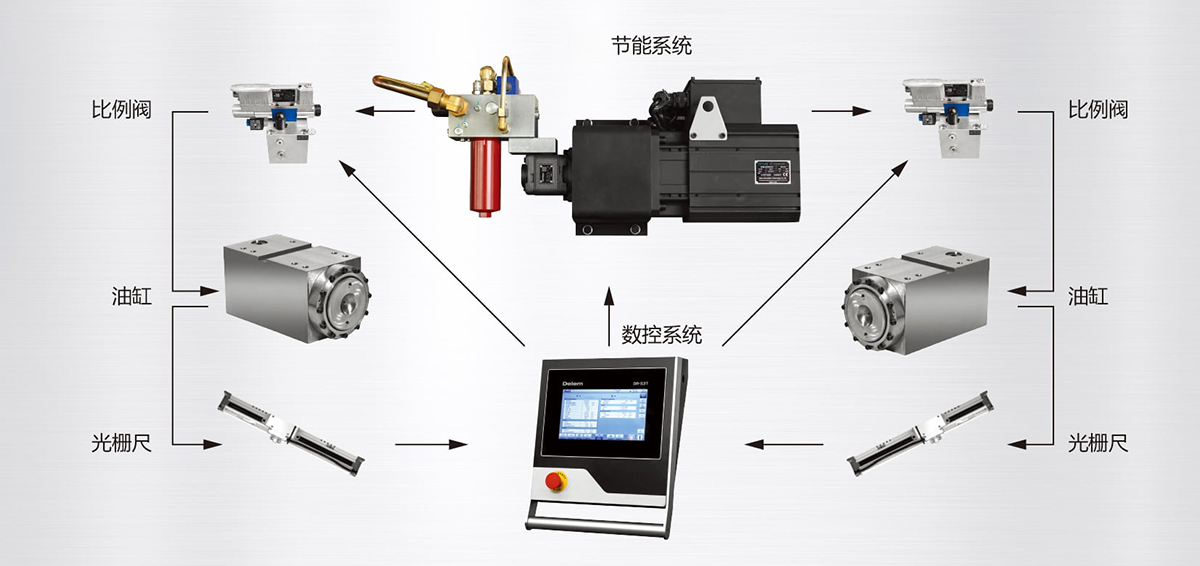

电液伺服系统配合瑞士进口光栅尺,能够精确控制滑块的位置和运动,实现高精度的折弯加工。

液压挠度自动补给系统,可消除滑块弯形对工件质量的影响,确保工件的平整度和精度。

驱动与传动:

后挡料采用台湾 HIWIN(上银)直线导轨及滚珠丝杠驱动,速度更快、精度更高。

原装进口集成液压控制系统减少了管路安装,克服了漏油问题,同时提高了系统的稳定性和可靠性。

模具安装:上模选用快速夹紧装置,减轻了工人的劳动强度,提高了生产效率。

一、 性能:

采用荷兰DeLem-DA53T或瑞士CYBELEC12系统是基本的数控系统,具有高效率的性能。美观现代、流线型铸塑外壳, 优雅而实用, 允许在底部面板安装用于机床操作的按钮和选择器开关。集成的DA-53T或(DA58T)数控系统有Delem二维图形编程设计工具,方便进行数控编程。有液压工序指定功能,可以让机器调整和测试工作减少。按键一次就可以生成数控程序,自动计算所有的轴位置直接进行生产。

数控系统采用先进新技术,高柔性、操作便捷USB接口提供了快速备份产品和模具。彩色的TFT显示和时尚的用户界面清晰,可为快速编程提供方便。DA-0ffine为离线编程提供解决方案。

二、设备特点:

本机床采用荷兰进口DeLem-DA53T数控系统或瑞士CYBELEC12系统。

具有人性化吊臂;基于实时的windows操作系统,二维彩色图形折弯机数控系统

DeLem-DA53T或瑞士CYBELEC12折弯机数控系统为使用者提供友好操作界面,高效率编程方式,和引以自豪稳定性集成于一体,将大大提高数控折弯机的工作效率。

图形编程技术秉承Delem或CYBELEC传统的编程优势,真实比例显示工件、模具和机床。

数控系统包括2D图形编程软件,具有折弯工序自动计算、工件干涉检测和自学习数据库,数据库运用将大大提高折弯精度。

全功能3D图形编程软件清晰展示真实机床模具配置以及折弯实现的可行性。

采用更高效率算法优化整个Y轴、X轴、R轴和补偿V轴工作循环,使得Y轴、X轴、R轴和补偿V轴循环的周期缩短,提高机床工作效率,同时对Y轴调整和控制更为方便。

三、设备性能介绍:(设备标配)

1、整机采用钢板焊接结构,并经整体振动处理;

2、一次装夹整体加工,保障机身的刚性和加工精度;

3、标准为数控4+1轴,Y1 、Y2、 X、R+ V;

4、电液伺服系统配合瑞士进口光栅尺,折弯精度更高;

5、液压挠度自动补给,消除滑块弯形对工件质量的影响;

6、原装进口集成液压控制系统减少管路安装,克服漏油;

7、后挡料采用台湾HIWIN(上银)直线导轨及滚珠丝杠驱动,速度更快精度更高;

8、上模选用快速夹紧,减轻工人劳动强度,提高生产效率;

9、可选配荷兰DELEM系统或瑞士CYBELEC系统;

10、可根据用户需要,后定位可控制六轴;

11、可选配液压上模夹紧。

12、增加数控(轴)调节功能另行商议。

四、 数控折弯机技术参数表(Technical Parameter Table of CNC Plate Bending Machine):

设备型号 Equipment Model | 公称力 Nominal Pressure of Slide | 工作台长度 Worktable Length | 立柱间距 Distance Between Columns | 喉口深度 Throat Depth | 滑块行程 slider stroke | 最大开启高度 Maximum opening height | 主电机功率 Main motor power | 设备外型尺寸 Overall dimensions of the equipment |

| (KN) | (mm) | (mm) | (mm) | (mm) | (mm) | (KW) | 长*宽*高(mm) | |

| 40/2200 | 400 | 2200 | 1850 | 250 | 100 | 350 | 5.5 | 2560*1300*1900 |

| 40/2500 | 400 | 2500 | 2150 | 250 | 100 | 350 | 5.5 | 2860*1300*1900 |

| 50/2500 | 500 | 2500 | 2150 | 250 | 100 | 350 | 5.5 | 2860*1300*1900 |

| 63/2500 | 630 | 2500 | 2150 | 250 | 120 | 350 | 5.5 | 3060*1380*2200 |

| 63/3200 | 630 | 3200 | 2580 | 250 | 120 | 350 | 5.5 | 3860*1430*2200 |

| 80/3200 | 800 | 3200 | 2580 | 320 | 120 | 350 | 7.5 | 3860*1510*2300 |

| 80/4000 | 800 | 4000 | 2980 | 320 | 120 | 350 | 7.5 | 4660*1430*2300 |

| 100/3200 | 1000 | 3200 | 2580 | 320 | 130 | 435 | 7.5 | 3860*1480*2450 |

| 100/4000 | 1000 | 4000 | 2980 | 320 | 130 | 450 | 7.5 | 4660*1530*2450 |

| 125/3200 | 1250 | 3200 | 2580 | 320 | 130 | 435 | 11 | 3900*1550*2550 |

| 125/4000 | 1250 | 4000 | 2980 | 320 | 130 | 435 | 11 | 4500*1580*2550 |

| 160/3200 | 1600 | 3200 | 2580 | 320 | 150 | 470 | 11 | 3900*1600*2800 |

| 160/4000 | 1600 | 4000 | 3000 | 320 | 150 | 470 | 11 | 4720*1650*2850 |

| 160/5000 | 1600 | 5000 | 4000 | 320 | 150 | 470 | 11 | 5760*1750*;2900 |

| 160/6000 | 1600 | 6000 | 5000 | 320 | 150 | 470 | 11 | 6700*1780*3000 |

| 200/3200 | 2000 | 3200 | 2580 | 400 | 200 | 500 | 15 | 3900*1650*2800 |

| 200/4000 | 2000 | 4000 | 3000 | 400 | 200 | 500 | 15 | 4560*1650*2800 |

| 200/5000 | 2000 | 5000 | 4000 | 400 | 200 | 500 | 15 | 5700*1700*2900 |

| 200/6000 | 2000 | 6000 | 5000 | 400 | 200 | 500 | 15 | 6600*1700*3000 |

| 250/4000 | 2500 | 4000 | 3000 | 400 | 200 | 560 | 18.5 | 4700*1700*3000 |

| 250/5000 | 2500 | 5000 | 4000 | 400 | 200 | 560 | 18.5 | 5760*1700*3100 |

| 250/6000 | 2500 | 6000 | 5000 | 400 | 200 | 560 | 18.5 | 6700*1800*3150 |

| 300/4000 | 3000 | 4000 | 3000 | 400 | 250 | 560 | 22 | 4660*2000*3000 |

| 300/5000 | 3000 | 5000 | 4000 | 400 | 250 | 560 | 22 | 5700*2000*3100 |

| 300/6000 | 3000 | 6000 | 5000 | 400 | 250 | 560 | 22 | 6720*2100*3200 |

| 600/4000 | 4000 | 4000 | 3000 | 400 | 250 | 570 | 22 | 4700*2000*3100 |

| 400/5000 | 4000 | 5000 | 4000 | 400 | 250 | 570 | 22 | 5760*2000*3200 |

| 400/6000 | 4000 | 6000 | 5000 | 400 | 250 | 570 | 22 | 6760*2100*3300 |

| 500/4000 | 5000 | 4000 | 3000 | 400 | 250 | 590 | 37 | 4760*2300*3500 |

| 500/5000 | 5000 | 5000 | 4000 | 400 | 250 | 590 | 37 | 5760*2300*3500 |

| 500/6000 | 5000 | 6000 | 5000 | 400 | 250 | 590 | 37 | 6760*2300*3600 |

| 600/4000 | 6000 | 4000 | 3000 | 400 | 250 | 610 | 45 | 4760*2400*3600 |

| 600/5000 | 6000 | 5000 | 4000 | 400 | 250 | 610 | 45 | 5800*2400*3600 |

| 600/6000 | 6000 | 6000 | 5000 | 400 | 250 | 610 | 45 | 6860*2500*3700 |

(上述设备可选配机械手自动上料系统、支持增加数控轴,支持非标设备定制)

以上参数如有变动,恕不另行通知,本公司保留对此资 料的最终解释权!