服务热线

13905146213

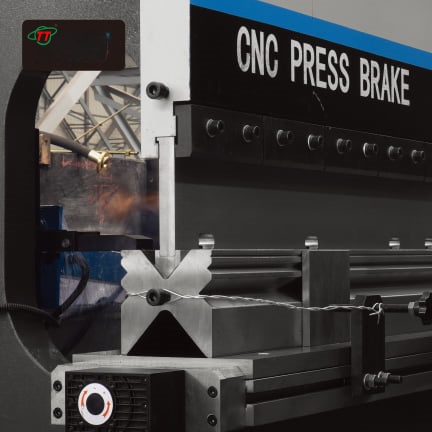

TP10S合资数控系统扭轴数控折弯机的工作原理如下:

一、TP10S数控折弯机基本配置

1、采用南京合资品牌TP10S数控系统。

2、采用全钢焊接结构,振动消除应力,折弯机强度高,刚性好;5、上模配有挠度补偿机构。上下模具均采用特殊高耐磨材料精加工而成。

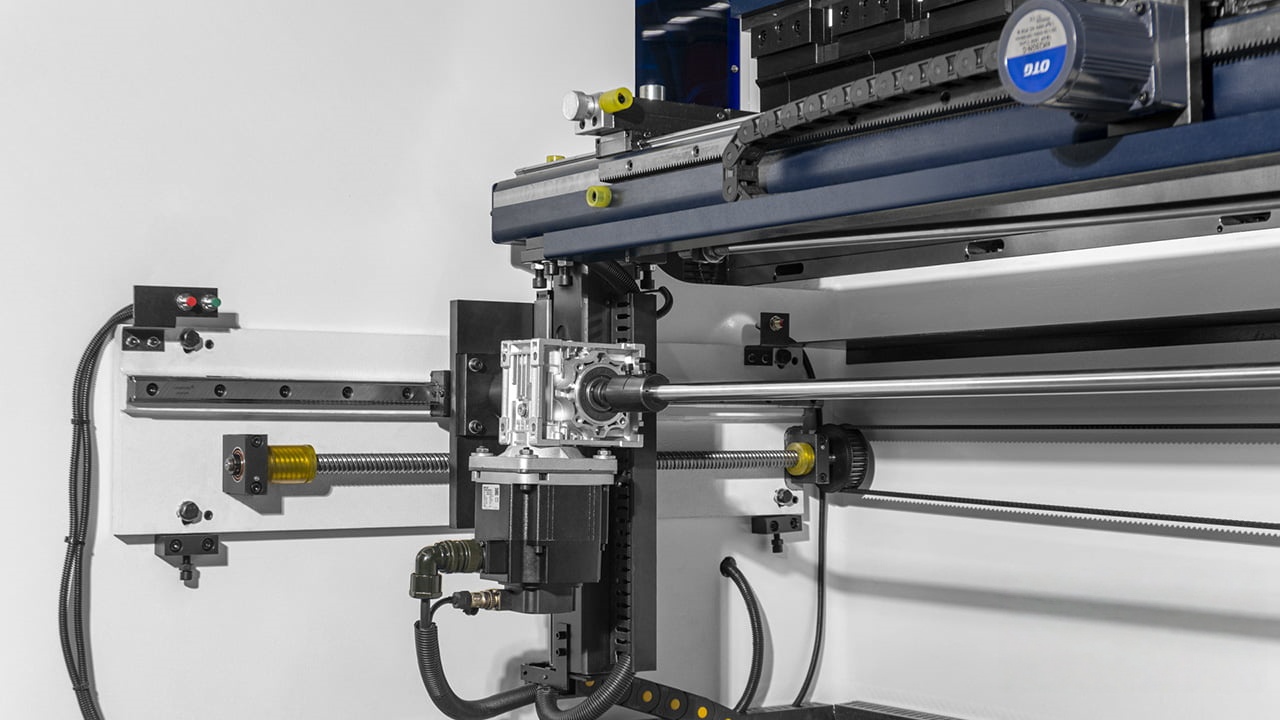

二、HT67K-TP10S为扭轴型折弯机所设计

1、5.7英寸液晶显示,全中文画面,数字输入,无须代码,按键式页面。

2、控制对象:伺服电机、步进电机;

3、控制轴数:由单轴至三轴,即扭轴,后挡位X轴及后挡位升降,挡手左右调整;油缸尺寸(角度)Y1轴和油缸角度尺寸(角度)Y2轴都可以一次性编成,一次性操作完成所需工件。

4、最小指令单位:0.01mm;

5、控制精度:0~0.01mm(不包括机械误差);6、位置指令范围:0~999.9mm;

7、最高输出频率:100KHz;

8、数据储存:可存50组,数据每组20个工作步骤,即总数据存储可达1000个数据,于工作中可任意提取。

9、后挡料退让功能:可于参数内设定是否退让及退让的长度;/9、后退让延时功能:根据板材厚与薄调整滑板下压与退让时间;

10、运行禁止功能:当扭轴运行后挡料运行时,机床不能动作;11、到数禁止功能:可设定加工数量,当加工次数到位后机床可禁止动作;/12、工步延时功能:即完成当前工步,开始下一步的时间;

12、选刀功能:在某一组数据内20个工步可任意提取所需工步进行调整;

13、单向功能:消除丝杆本身的间隙。

三、HT67K-TP10S二轴数控折弯机技术参数表(Technical Parameter Table of HT67K-DA53T Two-Axis CNC Bending Machine):

| 设备型号 Equipment Model | 公称压力 Nominal Pressure of Slide | 工作台长度 Worktable Length | 立柱间距 Distance Between Columns | 喉口深度 Throat depth | 滑块行程 Slide Stroke” “Ram stroke | 最大开启高度 Maximum opening height | 主电机功率 Main motor power | 设备外型尺寸 Overall dimensions of the equipment |

| (KN) | (mm) | (mm) | (mm) | (mm) | (mm) | (KW) | 长*宽*高(mm) | |

| 40/2200 | 400 | 2200 | 1850 | 250 | 100 | 350 | 5.5 | 2560*1300*1900 |

| 40/2500 | 400 | 2500 | 2150 | 250 | 100 | 350 | 5.5 | 2860*1300*1900 |

| 50/2500 | 500 | 2500 | 2150 | 250 | 100 | 350 | 5.5 | 2860*1300*1900 |

| 63/2500 | 630 | 2500 | 2150 | 250 | 120 | 350 | 5.5 | 3060*1380*2200 |

| 63/3200 | 630 | 3200 | 2580 | 250 | 120 | 350 | 5.5 | 3860*1430*2200 |

| 80/3200 | 800 | 3200 | 2580 | 320 | 120 | 350 | 7.5 | 3860*1510*2300 |

| 80/4000 | 800 | 4000 | 2980 | 320 | 120 | 350 | 7.5 | 4660*1430*2300 |

| 100/3200 | 1000 | 3200 | 2580 | 320 | 130 | 435 | 7.5 | 3860*1480*2450 |

| 100/4000 | 1000 | 4000 | 2980 | 320 | 130 | 450 | 7.5 | 4660*1530*2450 |

| 125/3200 | 1250 | 3200 | 2580 | 320 | 130 | 435 | 11 | 3900*1550*2550 |

| 125/4000 | 1250 | 4000 | 2980 | 320 | 130 | 435 | 11 | 4500*1580*2550 |

| 160/3200 | 1600 | 3200 | 2580 | 320 | 150 | 470 | 11 | 3900*1600*2800 |

| 160/4000 | 1600 | 4000 | 3000 | 320 | 150 | 470 | 11 | 4720*1650*2850 |

| 160/5000 | 1600 | 5000 | 4000 | 320 | 150 | 470 | 11 | 5760*1750*;2900 |

| 160/6000 | 1600 | 6000 | 5000 | 320 | 150 | 470 | 11 | 6700*1780*3000 |

| 200/3200 | 2000 | 3200 | 2580 | 400 | 200 | 500 | 15 | 3900*1650*2800 |

| 200/4000 | 2000 | 4000 | 3000 | 400 | 200 | 500 | 15 | 4560*1650*2800 |

| 200/5000 | 2000 | 5000 | 4000 | 400 | 200 | 500 | 15 | 5700*1700*2900 |

| 200/6000 | 2000 | 6000 | 5000 | 400 | 200 | 500 | 15 | 6600*1700*3000 |

| 250/4000 | 2500 | 4000 | 3000 | 400 | 200 | 560 | 18.5 | 4700*1700*3000 |

| 250/5000 | 2500 | 5000 | 4000 | 400 | 200 | 560 | 18.5 | 5760*1700*3100 |

| 250/6000 | 2500 | 6000 | 5000 | 400 | 200 | 560 | 18.5 | 6700*1800*3150 |

| 300/4000 | 3000 | 4000 | 3000 | 400 | 250 | 560 | 22 | 4660*2000*3000 |

| 300/5000 | 3000 | 5000 | 4000 | 400 | 250 | 560 | 22 | 5700*2000*3100 |

| 300/6000 | 3000 | 6000 | 5000 | 400 | 250 | 560 | 22 | 6720*2100*3200 |

| 600/4000 | 4000 | 4000 | 3000 | 400 | 250 | 570 | 22 | 4700*2000*3100 |

| 400/5000 | 4000 | 5000 | 4000 | 400 | 250 | 570 | 22 | 5760*2000*3200 |

| 400/6000 | 4000 | 6000 | 5000 | 400 | 250 | 570 | 22 | 6760*2100*3300 |

| 500/4000 | 5000 | 4000 | 3000 | 400 | 250 | 590 | 37 | 4760*2300*3500 |

| 500/5000 | 5000 | 5000 | 4000 | 400 | 250 | 590 | 37 | 5760*2300*3500 |

| 500/6000 | 5000 | 6000 | 5000 | 400 | 250 | 590 | 37 | 6760*2300*3600 |

| 600/4000 | 6000 | 4000 | 3000 | 400 | 250 | 610 | 45 | 4760*2400*3600 |

| 600/5000 | 6000 | 5000 | 4000 | 400 | 250 | 610 | 45 | 5800*2400*3600 |

| 600/6000 | 6000 | 6000 | 5000 | 400 | 250 | 610 | 45 | 6860*2500*3700 |

可选配有E21双轴数控系统,CT-8双轴数控系统,CT-10双轴或三轴数控系统,CT12三轴数控系统等

以上参数如有变动,恕不另行通知,本公司保留对此资料的最终解释权!