服务热线

13905146213

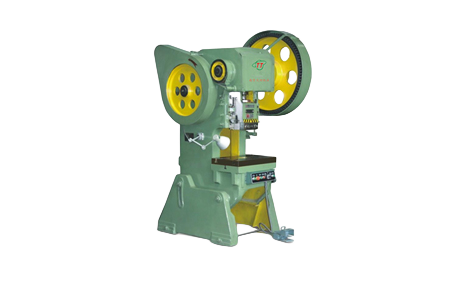

一、机械冲床是一种常见的金属加工设备,以下是关于它的详细介绍:

该系列压力机机身为可倾斜式铸造结构,倾斜时便于冲压件或废料从模具上滑下。采用刚性转键离合器,具有单次和连续操作规范。使用带式制动器,滑块装有压塌式保险器,超载时保险器被压塌,从而保证整机不受损坏。本机具有通用性强,精度高,性能可靠,便于操作的有点。配备自动送料装置可实现半自动冲压作业。

二、机械冲床部分规格技术参数(Technical Parameters of Some Specifications of Mechanical Punch Presses):

| 设备名称 Equipment model | 单位 | HT23-6.3 | HT23-10 | HT23-16 | HT23-25 | HT23-40 | HT23-63 | HT23-80 | HT23-100 | HT23-125 | HT23-160 | |

| 公称力 Nominal pressure | kN | 63 | 100 | 160 | 250 | 400 | 630 | 800 | 1000 | 1250 | 1600 | |

| 公称力行程 Stroke under nominal force | mm | 2.5 | 4 | 5 | 6 | 4 | 6 | 8 | 10 | 10 | 6 | |

| 滑块行程 Slider stroke | mm | 35 | 60 | 55/70 | 80 | 100 | 100 | 120 | 16-140 | 16-140 | 160 | |

| 行程次数 Number of strokes per minute | mm | 170 | 145 | 120 | 55 | 55 | 48 | 50 | 45 | 45 | 40 | |

| 最大封闭高度 Maximum closed height | mm | 150 | 180 | 220 | 250 | 220 | 270 | 360 | 400 | 400 | 550 | |

| 封闭高度调节量 Adjustment range of closed height | mm | 30 | 35 | 45 | 70 | 80 | 90 | 90 | 100 | 100 | 110 | |

| 滑块中心至机身距离Distance from the centerof the slider to the machine body | mm | 120 | 140 | 160 | 200 | 220 | 250 | 260 | 310 | 380 | 400 | |

| 工作台尺寸(前后*左右)Worktable size (front-to-back * left-to-right) | mm | 200*310 | 240*360 | 300*450 | 360*560 | 380*610 | 480*710 | 570*760 | 600*1020 | 600*1020 | 740*1300 | |

| 320*480 | ||||||||||||

| 工作台孔尺寸(直径*前后*左右) Size of the worktable hole (diameter * front-to-back * left-to-right) | mm | 100*120 | 100*120 | 160*160 | 200*200 | 200* 200 | 200* 200 | 220* 220 | 250**320 | 250**320 | 390*590 | |

| 工作台板厚度Thickness of the worktable plate | mm | 30 | 50 | 60 | 70 | 60 | 80 | 100 | 110 | 110 | 120 | |

| 滑块底面尺寸(直径*左右) Size of the bottom surface of the slider (diameter * left-to-right) | mm | 120*140 | 150*170 | 180*200 | 210*250 | 215*260 | 280*320 | 280*320 | 350*540 | 350*540 | 580*770 | |

| 模柄孔尺寸(直径*深度) Size of the die shank hole (diameter * depth) | mm | 30*50 | 35*50 | 40*60 | 40*70 | 50*80 | 50*80 | 50*80 | 60*80 | 60*80 | 65*90 | |

| 机身最大可倾角度 Maximum tilting angle of the fuselage | mm | |||||||||||

| 立柱间的距离 Distance between columns | mm | 170 | 200 | 240 | 350 | 360 | 450 | 450 | 720 | 720 | 810 | |

| 电动机 electric motor | 型号model | mm | Y90S-6 | Y90L-6 | Y100L-6 | Y100L1-4 | Y100L2-4 | Y160M-6 | Y132M-4 | Y132M-4 | Y180L-6 | |

| 功率 power | kW | 0.75 | 1.1 | 1.5 | 2.2 | 5.5 | 7.5 | 7.5 | 7.5 | 15 | ||

| 外形尺寸(长*宽*高) Overall dimensions (length * width * height) | mm | 1540* 700*1525 | 1510 *700*1660 | 1650* 840*1880 | 1790* 1100*2280 | 2130* 1050*2145 | 2180* 1250*2500 | 2220* 1350*2900 | 2060* 1350*2590 | 2060* 1150*2590 | 2590* 1390*3165 | |

| 重量/毛重 weight/gross weight | kg | 750/850 | 930/1030 | 1555/1800 | 2500 | 3100 | 4500 | 5600 | 9500 | 10000 | 19000 | |

| 出口包装尺寸(长*宽*高) Export packaging dimensions (length * width * height) | mm | 1800 *860*1780 | 1760* 850*1820 | 1900* 1100* 2120 | 2040* 1260*2540 | 2380* 1190*2395 | 2400* 1500*3100 | 2500 *16109*3210 | 2380* 1570*2920 | 2380* 15709*2920 | 3300* 1630*3565 |

注:本资料所列数据为参考数据,如与机床实际数据不符,应以机床实际数据为准,

以上参数如有变动,恕不另行通知,本公司保留对此资料的最终解释权!