服务热线

13905146213

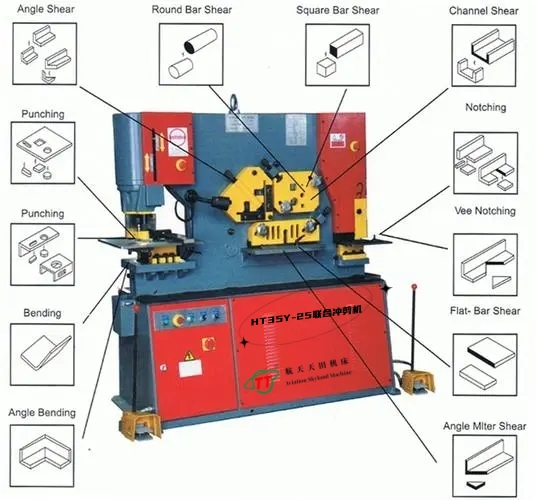

一、HT35Y系列液压联合冲剪机应用及工作原理

二、本机器特点:

2.液压传动,整体机床结构合理,重量轻,噪音低,轻便可靠,且具有保护性能。是以往机械联合冲剪机更新换代的一种新型产品。

3.适用于板材剪切、型材剪切、冲孔、板材折弯及模剪,还可作特殊形状的剪切冲压、弯曲等工序,可用于造船、电力、桥梁、汽车、起重运输、金属结构以及机械加工等部门。

4.可根据客户需要配备自动送料及自动卸料装置。

三、HT35Y液压联合冲剪机技术参数表:

| 型 号 model | HT35Y-16 | HT35Y-20 | HT35Y-25 | HT35Y-30 | HT35Y-40 | HT35Y-50 |

冲压力(T) punching pressure | 55 | 90 | 110 | 160 | 200 | 250 |

| 可剪最大板厚 mm(Maximum thickness of the plate that can be sheared) | 16 | 20 | 25 | 30 | 40 | 50 |

板料强度(N/MM²) Strength of the plate material | 450 | 450 | 450 | 450 | 450 | 450 |

剪切角° shearing angl | 7° | 8° | 8° | 8° | 8° | 8° |

一次行程剪板尺寸(厚*宽)mm Size of plate sheared in one stroke (Thickness * Width) | 16*250 | 20*330 | 25*330 | 30*355 | 40*450 | 50*600 |

| 8*400 | 10*480 | 16*600 | 20*600 | 40*800 | 50*800 | |

滑块行程(mm) Slider stroke | 80 | 80 | 80 | 80 | 80 | 80 |

形成次数(次/分) Number of strokes (times per minute) | 8 | 8 | 6 | 6 | 6 | 6 |

喉口深度(mm) throat depth | 300 | 355 | 400 | 600 | 600 | 600 |

冲孔厚度(mm) punching thickness | 16 | 20 | 25 | 26 | 26 | 26 |

| 最大冲孔直径(mm)Maximum punching diameter | 25 | 30 | 35 | 38 | 45 | 50 |

主电机功率(Kw) motor power | 4 | 5.5 | 7.5 | 11 | 15 | 22 |

外形尺寸长*宽*高(mm)Overall dimensions (length * width * height) | 1640*730*1770 | 1860*800*1900 | 2150*960*2100 | 2380*1040*2300 | 2750*1340*2500 | 3080*1560*2650 |

三、更换特殊模具也可剪切下列型材:(可选)Special molds can also be replaced to shear the following profiles: (Optional)

型钢种类 Types of section steel | 圆钢 round steel | 方钢 square steel | 等边角钢 equilateral angle stee | T型钢 T - section steel | 工型钢 universal beam | 槽钢 channel steel |

| HT35Y-16 | 45 | 40*40 | 125*125*12 70*70*8 | 120*120*12 60*60*8 | 126*74*5 | 126*53*5.5 |

| HT35Y-20 | 50 | 50*50 | 140*140*12 70*70*10 | 140*140*12 70*70*10 | 160*86*6 | 160*60*6.5 |

| HT35Y-25 | 60 | 50*50 | 160*160*14 80*80*7 | 160*160*14 80*80*10 | 200*102*9 | 200*75*9 |

| HT35Y-30 | 65 | 55*55 | 180*180*16 80*80*10 | 180*180*16 80*80*10 | 280*124*10.5 | 280*86*11.5 |

本资料所列数据为参考数据,如与机床实际数据不符,应以机床实际数据为准,

以上参数如有变动,恕不另行通知,本公司保留对此资料的最终解释权!