服务热线

13905146213

一、 HT - TS-I 全自动台式数控光纤激光切管机或HT-TS-II全自动台式数控光纤激光坡口切管机工作原理及应用区域的介绍:

工作原理:

管材固定与定位:将待切割的管材放置在工作台上,并通过夹具或定位装置将其牢固固定,确保管材在切割过程中不会发生位移,保证切割精度。

激光发生与传输:数控系统控制光纤激光发生器产生高能量密度的激光束。激光束通过光纤传输至切割头,在切割头中,激光束被聚焦透镜聚焦,形成极小的坡口切割光斑,从而在管材表面产生极高的能量密度。

切割头运动控制:数控系统根据预先编制的切割程序,精确控制切割头沿着管材的切割路径进行移动。切割头不仅可以沿着管材的轴向和径向移动,还可以进行角度调整,以实现不同角度的坡口切割。

辅助气体作用:在切割过程中,辅助气体(如氧气、氮气等)通过切割头喷出。辅助气体一方面可以吹走管材在激光作用下熔化或汽化的材料,另一方面可以保护切割头的镜片,防止飞溅物对其造成损坏。同时,不同的辅助气体在切割不同材质的管材时,还能起到促进切割过程、提高切割质量的作用。

坡口切割参数控制:操作人员根据管材的材质、壁厚、坡口角度等因素,在数控系统中设置合适的激光功率、切割速度、辅助气体压力等切割参数。数控系统根据这些参数精确控制激光发生器、切割头和辅助气体系统的工作,以达到理想的坡口切割效果。

应用区域:

建筑行业:用于建筑结构中管材的加工,如钢结构建筑中的钢管连接部位的坡口切割。可以切割出不同角度的坡口,方便管材之间的焊接,提高建筑结构的强度和稳定性。

机械制造行业:在机械零部件的加工中,台式数控光纤激光坡口切管机可用于切割各种管材,如液压缸体、机械臂管材等。能够满足不同机械对管材坡口精度和质量的要求,提高机械产品的性能和可靠性。

石油化工行业:适用于石油化工管道的加工,如油管、气管等。可以切割出符合工艺要求的坡口,保证管道连接的密封性和强度,防止泄漏等问题的发生。

汽车制造行业:用于汽车底盘、车架等部位的管材加工。可以切割出精确的坡口,便于管材的组装和焊接,提高汽车的安全性和性能。

航空航天行业:在航空航天领域,对管材的加工精度和质量要求极高。台式数控光纤激光坡口切管机可以切割出高精度的坡口,满足航空航天零部件的加工需求,如飞机发动机管道、机身结构管材等的加工。

船舶制造行业:可用于船舶管道系统和结构件的管材加工,如船舶的冷却管道、船体结构管材等。能够切割出合适的坡口,提高船舶管道连接的可靠性和船体结构的强度。

二、 HT - TS-I 全自动台式数控光纤激光切管机或HT-TS-II全自动台式数控光纤激光坡口切管机通常具有以下外观特点和组成部分:

工作台面:位于设备的底部,是一个平整的平台,用于放置待切割的管材。台面通常会有一些定位装置和夹具,用于固定管材,确保切割过程中管材不会移动。

管材输送装置:在工作台的一侧或两端,可能会有管材输送装置,用于将管材自动输送到切割位置。这可能包括滚轮、传送带或其他输送机构。

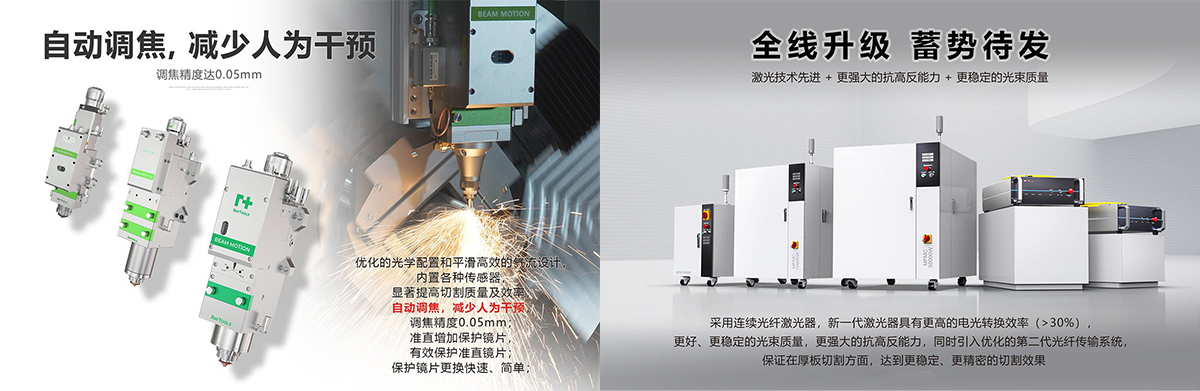

激光切割头:采用国内先进波刺激光切割头,这是设备的关键部件,位于工作台上方。激光切割头通过光纤与Raycus激光发生器连接,它可以沿着管材的切割路径移动,并发射高能量密度的激光束进行切割。切割头通常还配备有辅助气体喷嘴,用于喷出辅助气体。

龙门架或悬臂结构:用于支撑激光切割头,并使其能够在工作台上方进行精确的移动。龙门架结构通常横跨整个工作台,而悬臂结构则从一侧伸出。

控制柜:采用国内柏楚4000+数控系统,数控系统位于设备的一侧,用于控制整个切管机的运行。数控系统控制柜上有操作面板,操作人员可以通过面板设置切割参数、编程和监控设备的运行状态。

激光发生器:采用国内优秀锐科(Raycus)激光器,锐科(Raycus)激光器,是一个独立的单元,放置在设备的附近。它产生高能量的激光束,通过光纤传输到切割头。激光发生器根据不同的管径大小、壁厚等因素而选择不同的HT - TS 系列台式数控光纤激光坡口切管机功率和规格及加工长度和配置卡盘等,以适应不同的切割需求。

辅助气体系统:包括气体储存罐和输送管道,用于向激光切割头提供辅助气体。不同的辅助气体(如空气、氧气、氮气等)可以根据管材的材质和切割要求进行选择。

HT - TS-I 全自动台式数控光纤激光切管机或HT-TS-II全自动台式数控光纤激光坡口切管机区别:HT - TS-I 全自动台式数控光纤激光切管机把普通波刺切割头更改能切割坡口的波刺激光切割头就能完成为HT-TS-II全自动台式数控光纤激光坡口切管机。

三、两卡盘或三卡盘结构 创新加工

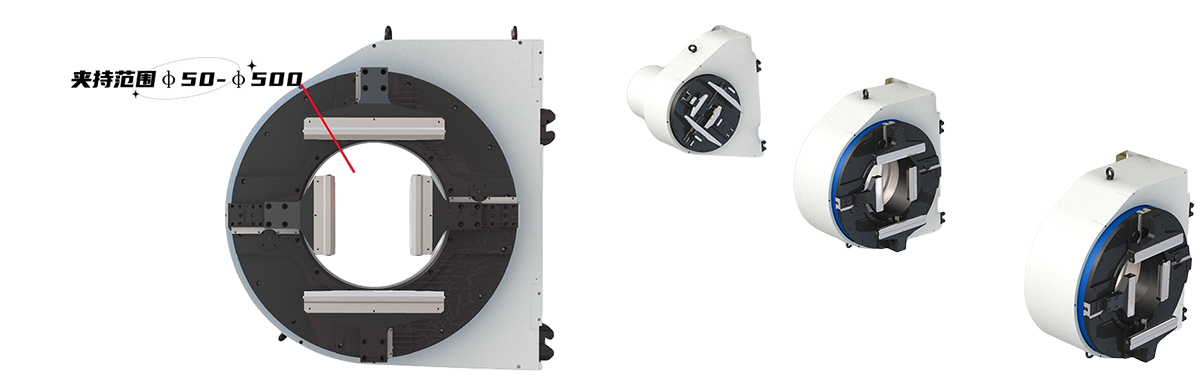

两卡盘或三卡盘结构设计,加工过程采用三个卡盘夹持支撑,可对管材的弯曲、扭曲较大的管材调整夹持力进行矫正切割,可避免因管料后端抖动而影响前端切割精度,运行速度快、精度高、载重高。

负载大、范围大

激光切管机的三卡盘结构,可避免因管料高速旋转抖动而影响切割精度和效率。夹持范围大,高承载力卡盘,最大夹持范围可达500mm,最大承载可达2吨,更大填补重型管材切割需求,卡爪夹持力智能可调,夹持范围可根据管材范围快速更换。

四、锐科(Raycus)激光器优点:

1.为用户节省成本。

2.切割6mm以下的金属板材只需要吹空气(普通空气0.6MPa-0.8MPa),而不需要氧气。节省使用氧气的费用。切割速度快于同类设备。

3.切割速度高于同类设备30%,切割速度达到每分钟4米。

4、重管多根上料 重载下料。

5、侧挂式导轨结构,防尘效果好;上料架型材上料,V型架接料,无需等待自动化程度高,质量最优。 对夹下料,可防止管材在运输和切割过程中滚动储料输送架,可存储多根管材,方便人员运输,节省时间。

五、机架组成及部分切割样品

六、HT - TS全自动台式数控光纤激光切管机特点说明:

1、本公司激光切割机采用先进国外进口IPG或Raycus(锐科)的激光器技术,光斑小,功率集中,割缝细、切割效率高,

2、采用柏楚4000+数控系统,采用优质先进的波刺黑金刚激光切割头。

3.设备框架采用龙门双丝杠、双伺服电机同步驱动,运行平稳,切割精度高。这种方式只有数百万元的大功率激光切割机采用。切割细线条、小圆等细小图案,不变形,效果好。采用焦距跟随设计,即使材料表面不平整仍可保证切割质量切缝平整、美观,无需后序处理工序。

4.人性化设计的控制柜,方便用户操作使用。

七、HT - TS全自动台式数控光纤激光切管机技术参数:

| 型号 | HT-TR-12050 | HT-TR-9050 | HT-TR-12036 | HT-TR-9036 | HT-TR-L13050 |

| 加工范围 | φ50-508mm | φ50-508mm | φ50-360mm | φ50-360mm | φ50-508mm |

| □50-350mm | □50-350mm | □50-260mm | □50-260mm | □50-350mm | |

| 定位精度 | ±0.03mm/m | ±0.03mm/m | ±0.03mm/m | ±0.03mm/m | ±0.03mm/m |

| 重复定位精度 | ±0.05mm | ±0.05mm | ±0.05mm | ±0.05mm | ±0.05mm |

| 最大空运行速度 | 40m/min | 40m/min | 60m/min | 60m/min | 40m/min |

| 最大空转速度 | 50r/min | 50r/min | 80r/min | 80r/min | 50r/min |

| 单根管材最大质量 | 2000kg | 2000kg | 1200kg | 1200kg | 1500kg |

| 最大一次性下料尺寸 | 12000mm | 9000mm | 12000mm | 9000mm | 13000mm |

| 推荐功率段 | 1000W-80000W | ||||

备注:本资料所列数据为参考数据,如与机床实际数据不符,应以机床实际数据为准,

以上参数如有变动,恕不另行通知,本公司保留对此资料的最终解释权!