服务热线

13905146213

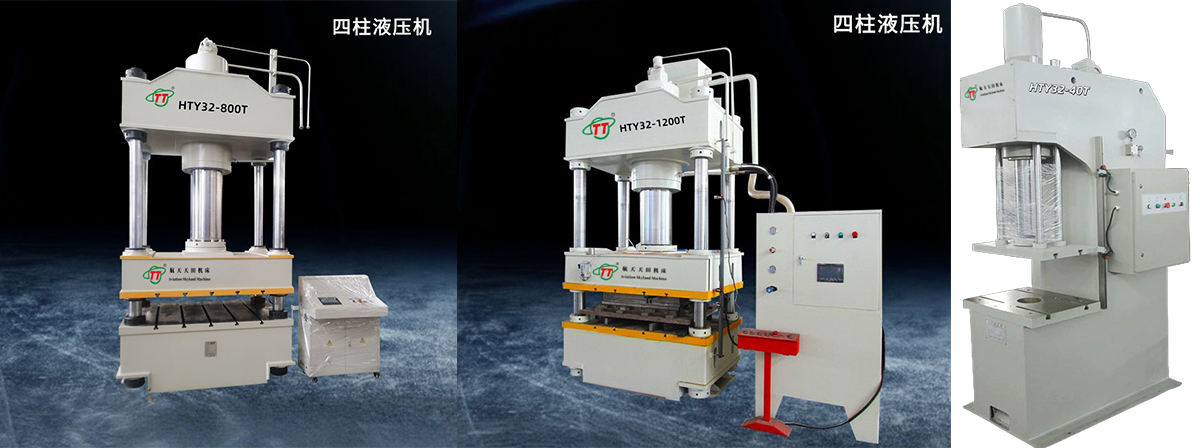

一、HT32 系列四柱油压机通常具有以下性能特点:

坚固的结构设计:采用三梁四柱式结构,经计算机优化设计。这种结构简单、经济且实用,能够提供稳定的支撑和可靠的压力输出,保证设备在长时间、高压力的工作状态下保持稳定的性能1。

先进的液压控制系统:液压控制采用插装阀集成系统,具有动作可靠、使用寿命长、液压冲击小的优点,同时减少了连接管路与泄漏点,提高了系统的稳定性和可靠性,降低了维护成本。

独立的电气控制系统:配备独立的电气控制系统,工作可靠,动作直观,维修方便。通过按钮集中控制,具备调整、半自动等操作方式,方便操作人员根据不同的工艺需求进行灵活设置和操作。

灵活的工艺调整功能:可通过操作面板选择,实现定程、定压两种成形工艺,并具有保压延时等功能。滑块的工作压力、空载快速下行和慢速工进的行程范围均可根据工艺需要在规定范围内进行调整,以适应不同的加工要求,提高了设备的通用性和适应性。

良好的安全性能:设置了多种安全保护装置,如急停按钮,按下后压机立即停止;滑块在上、下限位处均设有限位开关,防止滑块超出行程范围;在活塞式油缸下腔设置液压支承保险回路,液压系统中设有安全溢流阀,确保压机不会超载工作而损坏,此外还配备双手操作按钮,避免单人操作时可能出现的安全隐患。

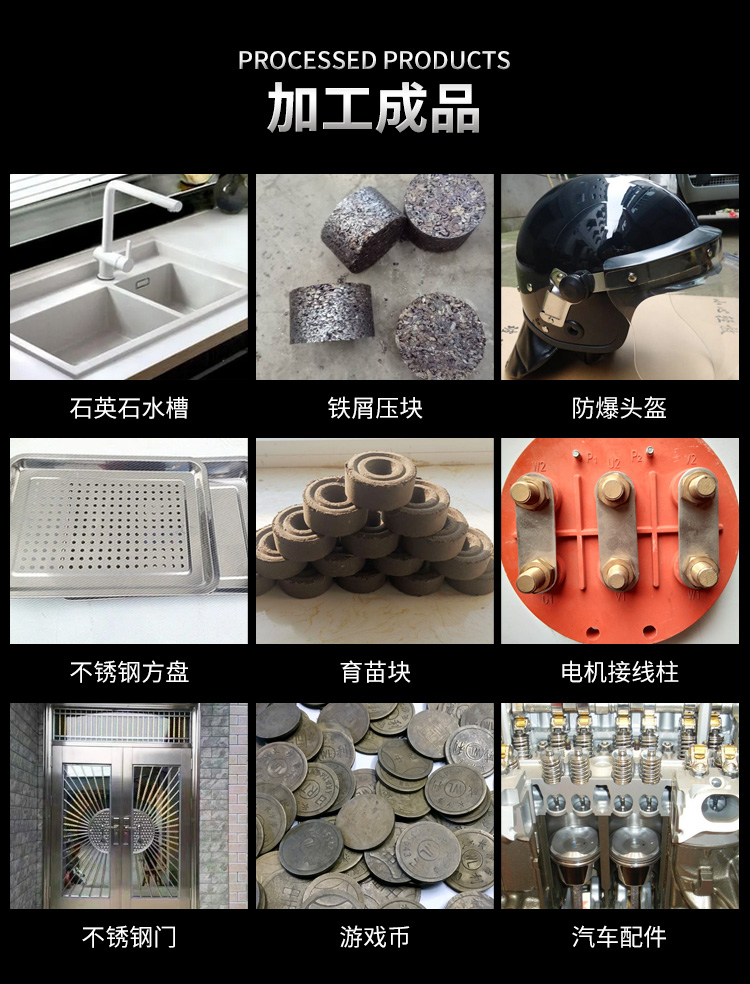

广泛的适用性:HT32系列适用于金属材料的拉伸、冲载(需选配冲载缓冲装置)、弯曲、翻边、冷挤压等多种冲压工艺,还可用于校正、压装、粉末制品和磨料制品的压制成型,以及塑料制品、绝缘材料的压制成型,能满足不同行业、不同产品的加工需求。

| 型 号 | 单位 | 40T | 63T | 100T | 200T | 315T | 400T | 500T | 630T | 1000T | |

| 公称力 | KN | 400 | 630 | 1000 | 2000 | 3150 | 4000 | 5000 | 6300 | 10000 | |

| 顶出力 | KN | 63 | 100 | 200 | 400 | 630 | 630 | 1000 | 1250 | 1000 | |

| 液体最大工作压力 | Mpa | 24.5 | 25 | 26.3 | 25 | 25 | 25 | 25.5 | 25 | 25 | |

| 滑块行程 | mm | 400 | 500 | 600 | 700 | 800 | 800 | 900 | 900 | 9000 | |

| 最大开口高度 | mm | 600 | 700 | 900 | 1100 | 1200 | 1400 | 1500 | 1500 | 1500 | |

| 顶出行程 | mm | 120 | 160 | 200 | 250 | 300 | 300 | 300 | 400 | 400 | |

| 滑块速度 | 空程下行 | m/s | 40 | 76 | 100 | 100 | 100 | 100 | 100 | >100 | 100 |

| 工作 | m/s | 10 | 10 | 8-15 | 8-15 | 8-15 | 8-15 | 8-15 | 10 | 12 | |

| 回程 | m/s | 60 | 60 | 60 | 70 | 70 | 70 | 80 | 65 | 80 | |

| 工作台尺寸 | 左右 | mm | 500 | 580 | 710 | 900 | 1260 | 1300 | 1400 | 1500 | 1500 |

| 前后 | mm | 460 | 500 | 580 | 900 | 1200 | 1300 | 1400 | 1500 | 1500 | |

| 机床 外形尺寸 | 左右 | mm | 970 | 2040 | 2150 | 3040 | 3250 | 3250 | 4100 | 4390 | 2340 |

| 前后 | mm | 1290 | 1200 | 1250 | 1600 | 1600 | 1600 | 2420 | 2520 | 3000 | |

| 地面上高度 | mm | 2525 | 3165 | 3570 | 4175 | 4400 | 4550 | 5348 | 5600 | 5800 | |

| 电机功率 | KW | 5.5 | 5.5 | 7.5 | 18.5 | 22 | 22 | 37 | 45 | 68 | |

| 总重量 | T | 2 | 3.2 | 4 | 10 | 14 | 20 | 27 | 38 | 48 | |

备注:本资料所列数据为参考数据,如与机床实际数据不符,应以机床实际数据为准,

以上参数如有变动,恕不另行通知,本公司保留对此资料的最终解释权!