一、 HT - TS-I 全自动台式数控光纤激光切管机或HT-TS-II全自动台式数控光纤激光坡口切管机工作原理及应用区域的介绍:

一、HT-TV-I全自动上料伺服随动数控光纤激光切管机(HT-TV-II全自动上料伺服随动数控光纤坡口激光切管机)工作原理及应用区域的介绍:

工作原理:

管材固定与定位:将待切割的管材放置在工作台上,并通过夹具或定位装置将其牢固固定,确保管材在切割过程中不会发生位移,保证切割精度。

激光发生与传输:数控系统控制光纤激光发生器产生高能量密度的激光束。激光束通过光纤传输至切割头,在切割头中,激光束被聚焦透镜聚焦,形成极小的坡口切割光斑,从而在管材表面产生极高的能量密度。

切割头运动控制:数控系统根据预先编制的切割程序,精确控制切割头沿着管材的切割路径进行移动。切割头不仅可以沿着管材的轴向和径向移动,还可以进行角度调整,以实现不同角度的坡口切割。

辅助气体作用:在切割过程中,辅助气体(如氧气、氮气等)通过切割头喷出。辅助气体一方面可以吹走管材在激光作用下熔化或汽化的材料,另一方面可以保护切割头的镜片,防止飞溅物对其造成损坏。同时,不同的辅助气体在切割不同材质的管材时,还能起到促进切割过程、提高切割质量的作用。

坡口切割参数控制:操作人员根据管材的材质、壁厚、坡口角度等因素,在数控系统中设置合适的激光功率、切割速度、辅助气体压力等切割参数。数控系统根据这些参数精确控制激光发生器、切割头和辅助气体系统的工作,以达到理想的坡口切割效果。

应用区域:

建筑行业:用于建筑结构中管材的加工,如钢结构建筑中的钢管连接部位的坡口切割。可以切割出不同角度的坡口,方便管材之间的焊接,提高建筑结构的强度和稳定性。

机械制造行业:在机械零部件的加工中,台式数控光纤激光坡口切管机可用于切割各种管材,如液压缸体、机械臂管材等。能够满足不同机械对管材坡口精度和质量的要求,提高机械产品的性能和可靠性。

石油化工行业:适用于石油化工管道的加工,如油管、气管等。可以切割出符合工艺要求的坡口,保证管道连接的密封性和强度,防止泄漏等问题的发生。

汽车制造行业:用于汽车底盘、车架等部位的管材加工。可以切割出精确的坡口,便于管材的组装和焊接,提高汽车的安全性和性能。

航空航天行业:在航空航天领域,对管材的加工精度和质量要求极高。台式数控光纤激光坡口切管机可以切割出高精度的坡口,满足航空航天零部件的加工需求,如飞机发动机管道、机身结构管材等的加工。

船舶制造行业:可用于船舶管道系统和结构件的管材加工,如船舶的冷却管道、船体结构管材等。能够切割出合适的坡口,提高船舶管道连接的可靠性和船体结构的强度。

I. Introduction to the working principle and application areas of the HT-TV-I full-automatic feeding servo follow-up CNC fiber laser pipe cutting machine (HT-TV-II full-automatic feeding servo follow-up CNC fiber laser bevel pipe cutting machine):

Working Principle:

Pipe Fixing and Positioning: Place the pipe to be cut on the workbench, and firmly fix it with clamps or positioning devices to ensure that the pipe will not move during the cutting process and guarantee the cutting accuracy.

Laser Generation and Transmission: The CNC system controls the fiber laser generator to generate a laser beam with high energy density. The laser beam is transmitted to the cutting head through the optical fiber. In the cutting head, the laser beam is focused by the focusing lens to form a very small bevel cutting spot, thus generating extremely high energy density on the surface of the pipe.

Cutting Head Movement Control: The CNC system precisely controls the cutting head to move along the cutting path of the pipe according to the pre-programmed cutting program. The cutting head can not only move axially and radially along the pipe but also adjust the angle to achieve bevel cutting at different angles.

Function of Auxiliary Gas: During the cutting process, auxiliary gases (such as oxygen, nitrogen, etc.) are ejected through the cutting head. On the one hand, the auxiliary gas can blow away the melted or vaporized material of the pipe under the action of the laser. On the other hand, it can protect the lens of the cutting head from being damaged by spatter. Meanwhile, different auxiliary gases can promote the cutting process and improve the cutting quality when cutting pipes of different materials.

Bevel Cutting Parameter Control: The operator sets appropriate cutting parameters such as laser power, cutting speed, and auxiliary gas pressure in the CNC system according to factors such as the material, wall thickness, and bevel angle of the pipe. The CNC system precisely controls the work of the laser generator, cutting head, and auxiliary gas system according to these parameters to achieve the ideal bevel cutting effect.

Application Areas:

Construction Industry: It is used for the processing of pipes in building structures, such as the bevel cutting of the connection parts of steel pipes in steel structure buildings. It can cut bevels at different angles, making it convenient for the welding of pipes and improving the strength and stability of the building structure.

Mechanical Manufacturing Industry: In the processing of mechanical parts, the desktop CNC fiber laser bevel pipe cutting machine can be used to cut various pipes, such as hydraulic cylinder bodies, pipes of robotic arms, etc. It can meet the requirements of different machines for the precision and quality of pipe bevels, improving the performance and reliability of mechanical products.

Petrochemical Industry: It is suitable for the processing of petrochemical pipes, such as oil pipes, gas pipes, etc. It can cut bevels that meet the technological requirements, ensure the sealing performance and strength of pipe connections, and prevent problems such as leakage.

Automobile Manufacturing Industry: It is used for the processing of pipes in parts such as the automobile chassis and frame. It can cut precise bevels, making it convenient for the assembly and welding of pipes and improving the safety and performance of automobiles.

Aerospace Industry: In the aerospace field, there are extremely high requirements for the processing precision and quality of pipes. The desktop CNC fiber laser bevel pipe cutting machine can cut high-precision bevels to meet the processing needs of aerospace components, such as the processing of pipes for aircraft engines and fuselage structure pipes.

Shipbuilding Industry: It can be used for the processing of pipes in the ship's pipeline system and structural parts, such as the cooling pipes of ships, hull structure pipes, etc. It can cut suitable bevels, improving the reliability of ship pipeline connections and the strength of the hull structure。

(HT-TV-I全自动上料伺服随动数控光纤激光切管机(HT-TV-II全自动上料伺服随动数控光纤坡口激光切管机工作视频)

The working video of the HT-TV-I full-automatic feeding servo follow-up CNC fiber laser pipe cutting machine (HT-TV-II full-automatic feeding servo follow-up CNC fiber laser bevel pipe cutting machine) (for reference)。

二、HT-TV-I全自动上料伺服随动数控光纤激光切管机(HT-TV-II全自动上料伺服随动数控光纤坡口激光切管机)控制系统是一套高度集成化、智能化的工业自动化系统,主要由以下核心组件构成:

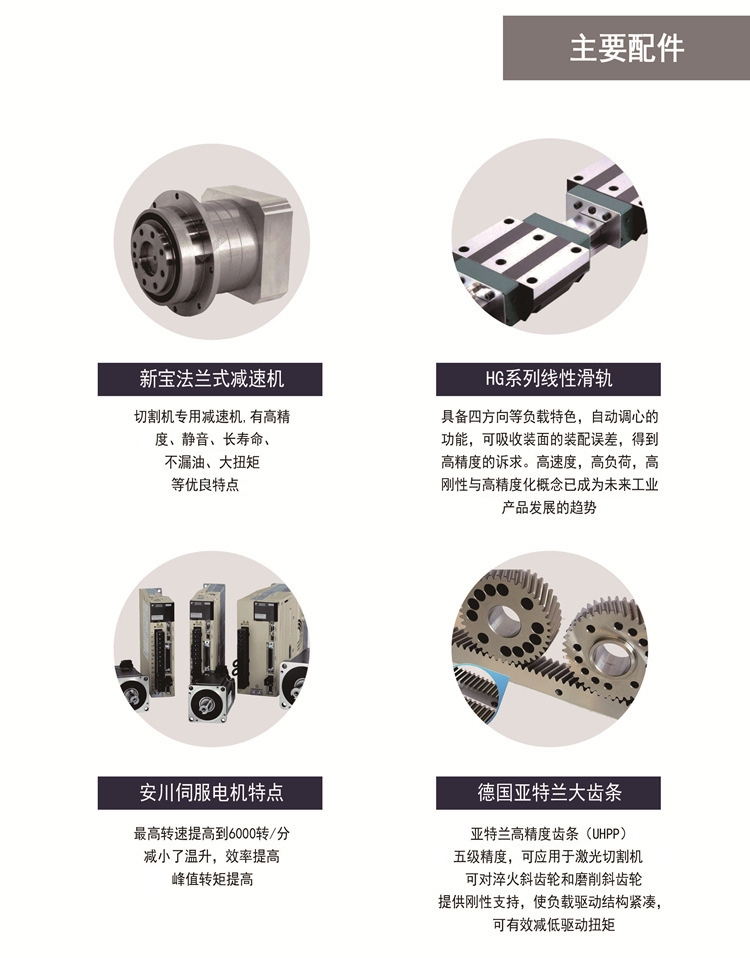

1.)柏楚 4000+ 数控系统

采用国内领先的柏楚电子控制系统,具备多轴联动控制能力(支持 X/Y/Z/A/C 轴同步运动)

配备 15.6 英寸工业级触控屏,分辨率达 1920×1080,支持手势操作和快捷键功能

内置高速处理器(Intel i5 或更高配置),运算速度达 3200 脉冲 / 秒,确保复杂轨迹的精确控制

2.)运动控制卡

采用自主研发的高精度运动控制卡,支持 EtherCAT 总线通讯协议

具备电子齿轮箱功能,可实现切割头与管材旋转的同步跟随

支持动态补偿算法,自动修正机械误差,定位精度达 ±0.03mm

)日本安川伺服电机

)伺服驱动器

)管材自动识别模块

)智能上料机器人

)激光功率控制系统

)波刺黑金刚切割头随动系统

电容式高度跟踪传感器,响应速度≤1ms

动态跟随范围 ±10mm,适应管材表面不平整

具备碰撞保护功能,接触力>5N 时自动停机

)操作软件

自主研发的 HT-Cut 3.0 专业切管软件,支持中文 / 英文界面切换

内置 200+ 种标准管材切割工艺库,覆盖碳钢、不锈钢、铝合金等材料

支持 DXF、DWG、IGES 等格式导入,自动生成切割路径

0远程监控模块

)多重安全联锁

)除尘与排烟系统

标配脉冲反吹式除尘器,过滤精度≤0.3μm

吸烟效率>95%,确保工作环境符合职业健康标准

风速传感器实时监测风道压力,异常时自动报警

这套控制系统通过各组件的协同工作,实现了从管材上料、定位、切割到下料的全自动化流程,切割效率比传统设备提升 30% 以上,适用于精密管材加工、工程机械制造、汽车零部件等高端制造领域。

II. The control system of the HT-TV-I full-automatic feeding servo follow-up CNC fiber laser pipe cutting machine (HT-TV-II full-automatic feeding servo follow-up CNC fiber laser bevel pipe cutting machine) is a highly integrated and intelligent industrial automation system, mainly composed of the following core components:

Core control unit

1.) Bodor 4000+ numerical control system

Adopt the leading Bodor electronic control system in China, with multi-axis linkage control capability (supporting synchronous movement of X/Y/Z/A/C axes)

Equipped with a 15.6-inch industrial-grade touch screen with a resolution of 1920×1080, supporting gesture operation and shortcut key functions

Built-in high-speed processor (Intel i5 or higher configuration), with an operation speed of 3200 pulses per second, ensuring precise control of complex trajectories

2.) Motion control card

Adopt the independently developed high-precision motion control card, supporting the EtherCAT bus communication protocol

Have the function of an electronic gearbox to achieve synchronous following of the cutting head and the rotation of the pipe

Support the dynamic compensation algorithm, automatically correct mechanical errors, and the positioning accuracy reaches ±0.03mm

Servo drive system

1.) Japanese Yaskawa servo motor

The X/Y/Z axes are standard equipped with 1.5kW high-response servo motors, with an acceleration of 1.5G

The A/C axes (rotary axes) adopt 2.2kW high-precision servo motors, with a minimum rotation resolution of 0.001°

The motor protection level reaches IP65, adapting to the industrial environment with a lot of dust

2.) Servo driver

Match the Yaskawa Sigma-7 series driver, supporting full closed-loop control

Built-in vibration suppression function, effectively reducing mechanical jitter during high-speed movement

Support regenerative energy recovery, and the energy-saving efficiency is increased by more than 20%

Automated feeding system

1.) Automatic pipe identification module

Adopt a 3D vision sensor (Keyence or Omron brand), which can automatically identify the pipe diameter (range Φ10-Φ220mm)

Support automatic measurement of the pipe length (maximum detection length of 6000mm)

Built-in AI algorithm, which can automatically match cutting process parameters

2.) Intelligent feeding robot

6-axis articulated robot (load of 20-50kg is optional), with a repeat positioning accuracy of ±0.05mm

Equipped with an adaptive fixture, supporting automatic grasping of round pipes, square pipes, and rectangular pipes

The feeding cycle is ≤ 8 seconds per time, and continuous operation for 24 hours can be achieved

Laser cutting control system

1.) Laser power control system

Deeply adapted to the Raycus laser, supporting stepless power adjustment from 0 to 100%

Built-in piercing expert system, which can automatically optimize piercing parameters according to the material thickness

Support the pulse cutting mode, with a frequency range of 1-5000Hz

2.) Wave-stimulation Black King Kong cutting head follow-up system

Capacitive height tracking sensor, with a response speed ≤ 1ms

Dynamic following range of ±10mm, adapting to the uneven surface of the pipe

Have a collision protection function, and automatically stop when the contact force > 5N

Human-machine interaction system

1.) Operation software

The independently developed HT-Cut 3.0 professional pipe cutting software supports the switching between Chinese and English interfaces

Built-in more than 200 standard pipe cutting process libraries, covering materials such as carbon steel, stainless steel, and aluminum alloy

Support the import of formats such as DXF, DWG, and IGES, and automatically generate cutting paths

2.) Remote monitoring module

Support 4G/5G/WiFi network connection, and the device status can be remotely monitored through the mobile phone APP

Built-in fault diagnosis system, which can automatically give early warnings and provide solutions

Support cloud storage and analysis of production data to achieve digital factory management

Safety protection system

1.) Multiple safety interlocks

The fully enclosed protective cabin door is equipped with an electromagnetic induction switch, and it will automatically stop when the door is opened

The laser protection level reaches Class 1, meeting the CE safety standard

Emergency stop buttons are distributed in each operation area of the equipment, with a response time < 0.1s

2.) Dust removal and smoke exhaust system

Standard pulse reverse blowing dust collector, with a filtration accuracy ≤ 0.3μm

The smoke suction efficiency > 95%, ensuring that the working environment meets the occupational health standard

The wind speed sensor monitors the air duct pressure in real time, and it will automatically alarm in case of an abnormality

Through the coordinated work of each component, this control system realizes the fully automated process from pipe feeding, positioning, cutting to unloading, and the cutting efficiency is increased by more than 30% compared with traditional equipment, which is suitable for high-end manufacturing fields such as precision pipe processing, construction machinery manufacturing, and automotive parts manufacturing

三、三卡盘结构 创新加工

三卡盘结构设计,加工过程采用三个卡盘夹持支撑,可对管材的弯曲、扭曲较大的管材调整夹持力进行矫正切割,可避免因管料后端抖动而影响前端切割精度,运行速度快、精度高、载重高。

Three Chuck Structure, Innovative Processing

With the design of the three chuck structure, during the processing, three chucks are used for clamping and supporting. For pipes with large bending and twisting, the clamping force can be adjusted for correction and cutting. It can prevent the cutting accuracy at the front end from being affected by the shaking of the rear end of the pipe material, featuring fast operation speed, high precision, and high load capacity.

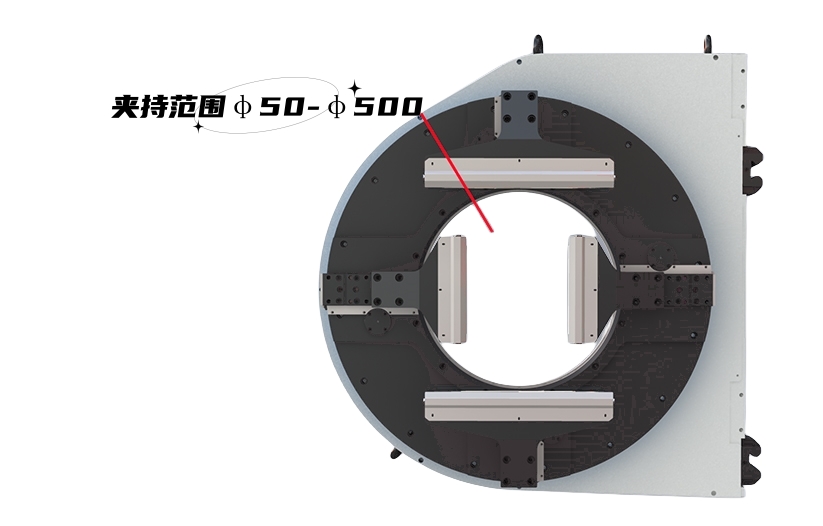

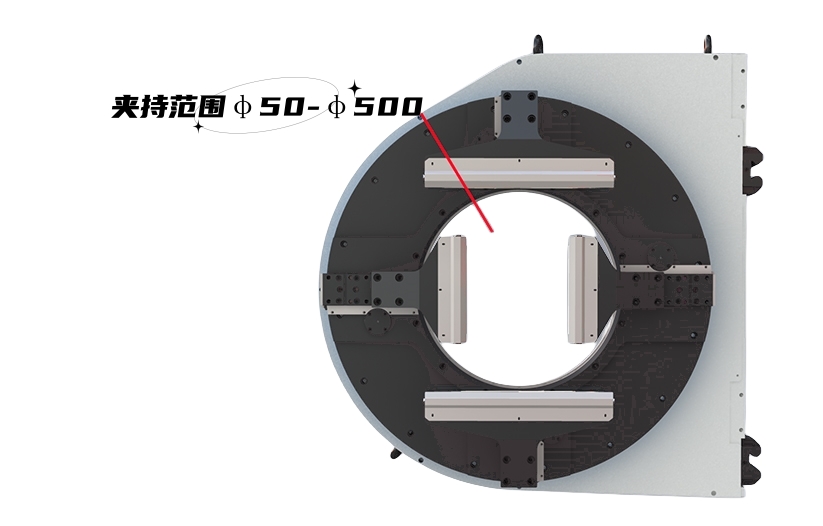

四、负载大、范围大

激光切管机的三卡盘结构,可避免因管料高速旋转抖动而影响切割精度和效率。夹持范围大,高承载力卡盘,可以完成多根圆管、方管、矩形钢等材料多根夹持;最小夹持范围可达15mm;最大夹持范围可达500mm,最大承载可达2吨,更大填补重型管材切割需求,卡爪夹持力智能可调,夹持范围可根据管材范围快速更换。

IV. Large Load and Wide Range

The three-chuck structure of the laser pipe cutting machine can prevent the cutting accuracy and efficiency from being affected by the jitter of the pipe material during high-speed rotation. With a large clamping range and high-load chucks, it can clamp multiple materials such as round pipes, square pipes, and rectangular steel. The minimum clamping range can reach 15mm, and the maximum clamping range can reach 500mm. The maximum load capacity can reach 2 tons, which better meets the cutting needs of heavy-duty pipes. The clamping force of the chuck jaws can be intelligently adjusted, and the clamping range can be quickly replaced according to the range of the pipes五、标配进口IPG激光器或Raycus锐科优质激光器的激光器优点:

1.为用户节省成本。

2.切割6mm以下的金属板材只需要吹空气(普通空气0.6MPa-0.8MPa),而不需要氧气。节省使用氧气的费用。切割速度快于同类设备。

3.切割速度高于同类设备30%,切割速度达到每分钟4米。

4、重管多根上料 重载下料。

5、侧挂式导轨结构,防尘效果好;上料架型材上料,V型架接料,无需等待自动化程度高,质量最优。 对夹下料,可防止管材在运输和切割过程中滚动储料输送架,可存储多根管材,方便人员运输,节省时间。

V. Advantages of the laser: The standard configuration includes imported IPG lasers or high-quality Raycus lasers:

Save costs for users.

When cutting metal sheets with a thickness of less than 6mm, only air (ordinary air at 0.6MPa - 0.8MPa) is required, and oxygen is not needed. This saves the cost of using oxygen. The cutting speed is faster than that of similar equipment.

The cutting speed is 30% higher than that of similar equipment, reaching 4 meters per minute.

Multiple heavy pipes can be loaded, and heavy-duty unloading is available.

The side-hanging guide rail structure has a good dust-proof effect; the material is loaded on the profile of the loading rack, and the V-shaped rack is used for receiving materials. There is no need to wait, and the degree of automation is high with the best quality. The opposite clamping unloading can prevent the pipes from rolling during transportation and cutting. The storage and conveying rack can store multiple pipes, which is convenient for personnel transportation and saves time

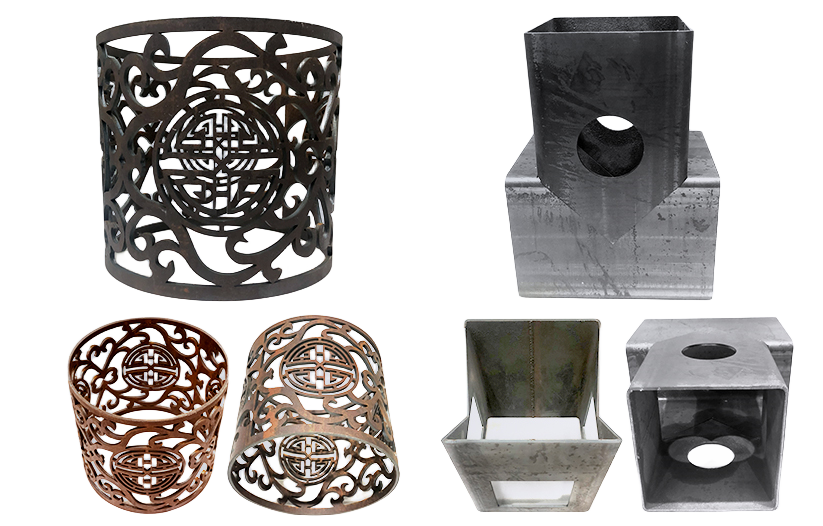

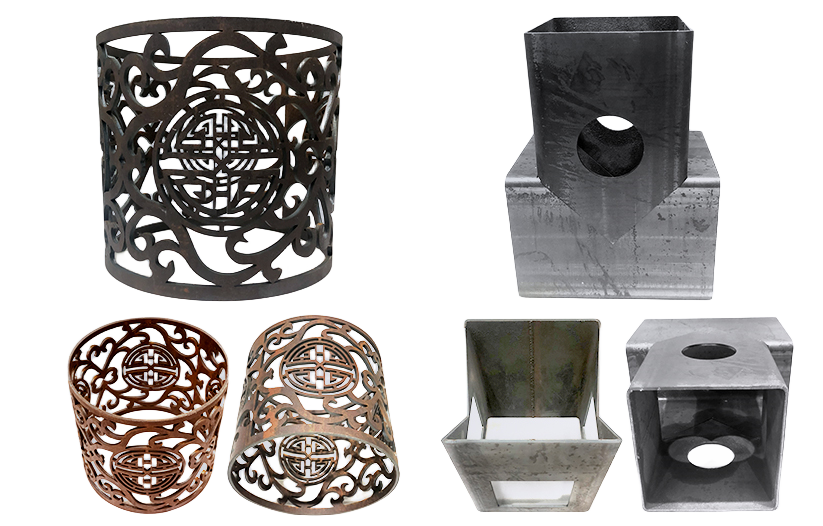

部分切割形状图(Partial cutting shape diagrams)

伺服随动全自动上料数控光纤激光切管机特点说明:

1、本公司激光切割机采用先进国外进口IPG或Raycus(锐科)的激光器技术,光斑小,功率集中,割缝细、切割效率高,

2、采用柏楚4000+数控系统,采用优质先进的波刺黑金刚激光切割头。

2.设备框架采用龙门双丝杠、双伺服电机同步驱动,运行平稳,切割精度高。这种方式只有数百万元的大功率激光切割机采用。切割细线条、小圆等细小图案,不变形,效果好。采用焦距跟随设计,即使材料表面不平整仍可保证切割质量切缝平整、美观,无需后序处理工序。

3.人性化设计的控制柜,方便用户操作使用。

Characteristics Description of Servo-following Full-automatic Loading CNC Fiber Laser Pipe Cutting Machine:

The laser cutting machine of our company adopts the laser technology of imported IPG or Raycus (Ruike) from abroad. It has a small light spot, concentrated power, a narrow cutting seam, and high cutting efficiency.

It adopts the Bechuan 4000+ CNC system and high-quality and advanced Black King Kong laser cutting head of Bosi.

The equipment frame is driven synchronously by a gantry double lead screw and double servo motors, which runs stably and has high cutting precision. This method is only used in high-power laser cutting machines worth several million yuan. It can cut fine lines, small circles and other small patterns without deformation, and the effect is good. It adopts the focal length following design. Even if the surface of the material is uneven, it can still ensure the cutting quality. The cutting seam is flat and beautiful, and there is no need for subsequent processing procedures.

The control cabinet with a humanized design is convenient for users to operate

六、伺服随动全自动上料数控光纤激光切管机技术参数:

型号 | HT-TR-12050 | HT-TR-9050 | HT-TR-12036 | HT-TR-9036 | HT-TR-L13050 |

加工范围 | φ50-508mm | φ50-508mm | φ50-360mm | φ50-360mm | φ50-508mm |

□50-350mm | □50-350mm | □50-260mm | □50-260mm | □50-350mm |

定位精度 | ±0.03mm/m | ±0.03mm/m | ±0.03mm/m | ±0.03mm/m | ±0.03mm/m |

重复定位精度 | ±0.05mm | ±0.05mm | ±0.05mm | ±0.05mm | ±0.05mm |

最大空运行速度 | 40m/min | 40m/min | 60m/min | 60m/min | 40m/min |

最大空转速度 | 50r/min | 50r/min | 80r/min | 80r/min | 50r/min |

单根管材最大质量 | 2000kg | 2000kg | 1200kg | 1200kg | 1500kg |

最大一次性下料尺寸 | 12000mm | 9000mm | 12000mm | 9000mm | 13000mm |

推荐功率段 | 1000W-80000W |

VI. Technical Parameters of the Servo-following Full-automatic Loading CNC Fiber Laser Pipe Cutting Machine:

| Processing Range | φ50-508mm

□50-350mm | φ50-508mm

□50-350mm | φ50-360mm

□50-260mm | φ50-360mm

□50-260mm | φ50-508mm

□50-350mm |

| Positioning Accuracy | ±0.03mm/m | ±0.03mm/m | ±0.03mm/m | ±0.03mm/m | ±0.03mm/m |

| Repeat Positioning Accuracy | ±0.05mm | ±0.05mm | ±0.05mm | ±0.05mm | ±0.05mm |

| Maximum Idle Running Speed | 40m/min | 40m/min | 60m/min | 60m/min | 40m/min |

| Maximum Idle Speed | 50r/min | 50r/min | 80r/min | 80r/min | 50r/min |

| Maximum Mass of a Single Pipe | 2000kg | 2000kg | 1200kg | 1200kg | 1500kg |

| Maximum One-time Unloading Size | 12000mm | 9000mm | 12000mm | 9000mm | 12000mm |

备注:本资料所列数据为参考数据,如与机床实际数据不符,应以机床实际数据为准,以上参数如有变动,恕不另行通知,本公司保留对此资料的最终解释权!

Remarks: The data listed in this document are for reference. In case of any discrepancy with the actual data of the machine tool, the actual data of the machine tool shall prevail. The above parameters are subject to change without prior notice. Our company reserves the right to interpret this document!