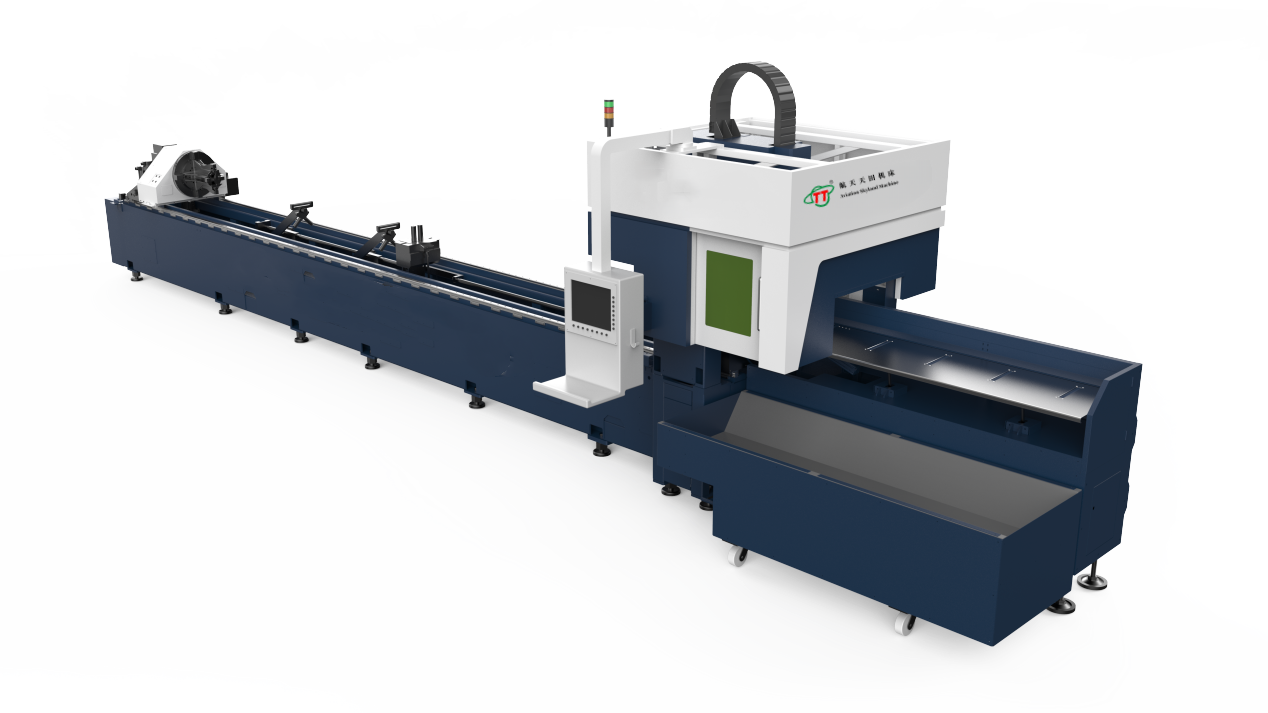

外观颜色可根据客户要求选配,设备外观图片与式样,供参考,供参考。(The appearance color can be selected according to customer requirements. The appearance pictures and styles of the equipment are for reference only)。

一、技术优势:

1、采用IPG光纤激光器或Raycus锐科光纤激光器和激光电源

IPG光纤激光器或锐科光纤激光器,模块化和冗余设计;体积小巧,重量轻,便于移动;易于集成,其性能稳定、产品整体质量得到安全保障。

I. Technical Advantages:

Use IPG fiber lasers or Raycus fiber lasers and laser power supplies.

IPG fiber lasers or Raycus fiber lasers feature modular and redundant designs. They are compact in size and light in weight, making them easy to move. They are also easy to integrate, and their stable performance ensures the safety of the overall product quality.

(图片仅供参考,以实物为准The picture is for reference only. Please refer to the actual product)

二、IPG光纤激光器或Raycus锐科光纤激光器光纤激光器的主要特点:

1、主要基本功能

1) 光纤激光器电-光转化效率高,转换效率达30%以上,可大幅度节约工作时的耗电,节省运行成本,达到较高的生产效率;

2) 激光器运行时仅仅需要电能,不需要产生激光的额外气体,具有较低的运行和维护费用;

3) 光纤激光器采用半导体模块化和冗余设计,谐振腔内无光学镜片,不需要启动时间,具有免调节、免维护、高稳定性的优点,降低了配件成本和维护的时间,这是传统激光器无法比拟的;

4) 光纤激光器的输出波长为1.06微米,是CO2波长的1/10,输出的光束质量好,功率密度高,有利于金属材料的吸收,具有卓越的切割、焊接能力,从而使加工的费用降低;

5) 整机光路由光纤传输,不需要复杂的反射镜等导光系统,光路简单,结构稳定,外光路免维护;

6) 光通过光纤导出,使机械系统的设计变得非常简单,非常容易与机器人或多维工作台集成;

7) 激光器加上光闸后可以一器多机,通过光纤分光,分成多路多台同时工作,易于扩展功能,升级方便、简单;

8) 光纤激光器体积小,重量轻,工作位置可移动,占地面积小;

2、波刺黑金刚自动变焦激光头

1)焦点可自动调节,适用多种焦距;

2)电容式传感、全自动随动系统;

3)采用复合镜片、内置水冷结构;

4)准直和聚焦组件的双水冷恒温保证;

5)采用抽屉式镜座,更换保护镜片快速; 平滑高效气流设计;

6)适配各种光纤激光器;

7)短、长焦距通用,可实现薄或厚板良好的切割效果;

8)全部配备准直保护镜,更好的防护准直镜;

9)QBH圆周位置可调,保证每台QBH红点朝外,方便光纤头的插拔;

10)焦点位置可视窗口,确保输入焦点与输出焦点准确一致;

II. Main Features of IPG Fiber Lasers or Raycus Fiber Lasers:

Main Basic Functions

Fiber lasers have high electro-optical conversion efficiency, with a conversion efficiency of over 30%. This can significantly save power consumption during operation, reduce operating costs, and achieve high production efficiency.

When the laser operates, it only requires electrical energy and does not need additional gases for laser generation, resulting in low operation and maintenance costs.

Fiber lasers adopt semiconductor modular and redundant designs. There are no optical lenses in the resonant cavity, and no start-up time is required. They have the advantages of being free from adjustment, maintenance-free, and highly stable, reducing the cost of accessories and maintenance time, which is unparalleled by traditional lasers.

The output wavelength of fiber lasers is 1.06 microns, which is 1/10 of the CO2 wavelength. The output beam has good quality and high power density, which is conducive to the absorption of metal materials and has excellent cutting and welding capabilities, thereby reducing processing costs.

The optical path of the entire machine is transmitted through optical fibers, eliminating the need for complex light guiding systems such as mirrors. The optical path is simple, and the structure is stable. The external optical path is maintenance-free.

Since the light is exported through optical fibers, the design of the mechanical system becomes very simple, and it is very easy to integrate with robots or multi-dimensional workbenches.

After adding a shutter to the laser, one laser can serve multiple machines. Through optical fiber beam splitting, it can be divided into multiple channels for multiple machines to work simultaneously, making it easy to expand functions, and the upgrade is convenient and simple.

Fiber lasers are small in size, light in weight, and the working position is movable, with a small footprint.

Wave Thorn Black King Kong Automatic Zoom Laser Head

The focal point can be automatically adjusted, suitable for various focal lengths.

Capacitive sensing, fully automatic follow-up system.

Adopts composite lenses and a built-in water cooling structure.

Double water cooling and constant temperature assurance for the collimation and focusing components.

Adopts a drawer-type mirror base for quick replacement of the protective lens; smooth and efficient airflow design.

Compatible with various fiber lasers.

Both short and long focal lengths are applicable, and good cutting effects on thin or thick plates can be achieved.

All are equipped with collimation protection lenses to better protect the collimating mirror.

The circumferential position of QBH is adjustable to ensure that the red dot of each QBH faces outward, facilitating the insertion and extraction of the optical fiber head.

The focal point position has a visible window to ensure that the input focal point is accurately consistent with the output focal point.

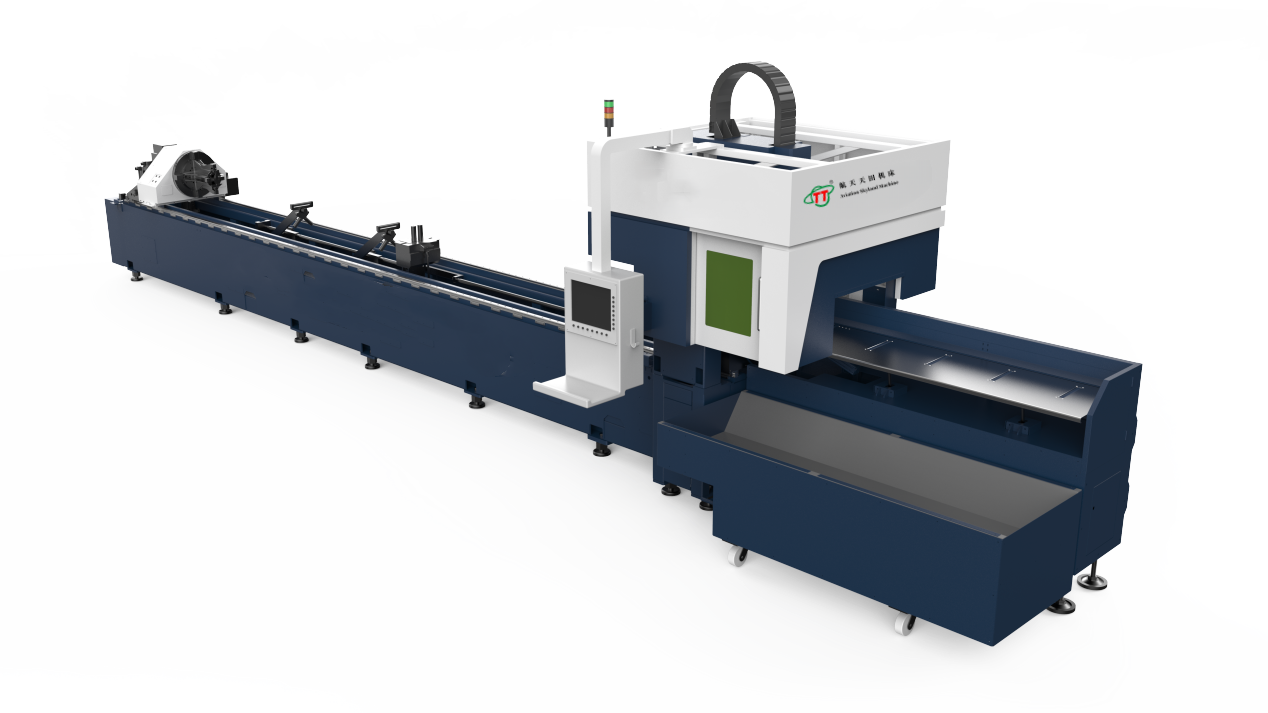

三、HT-TP系列重载型数控光纤激光切管机简介:

1、HT-TP系列重载型激光切管机。

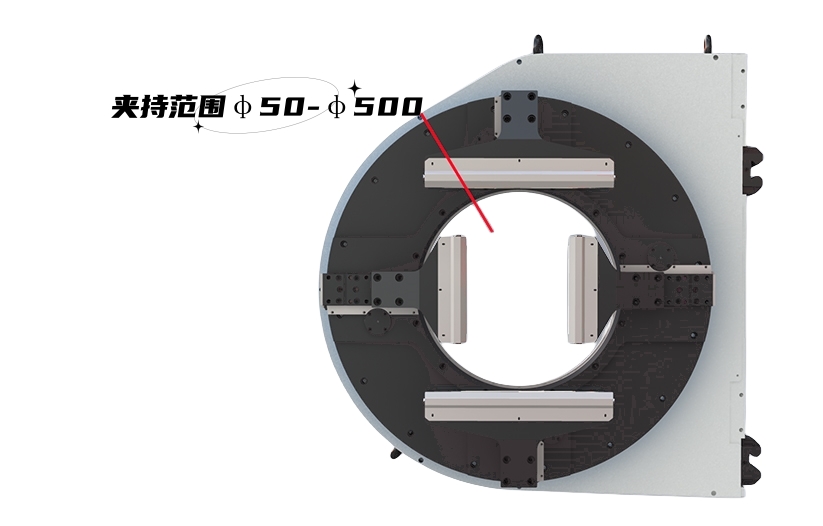

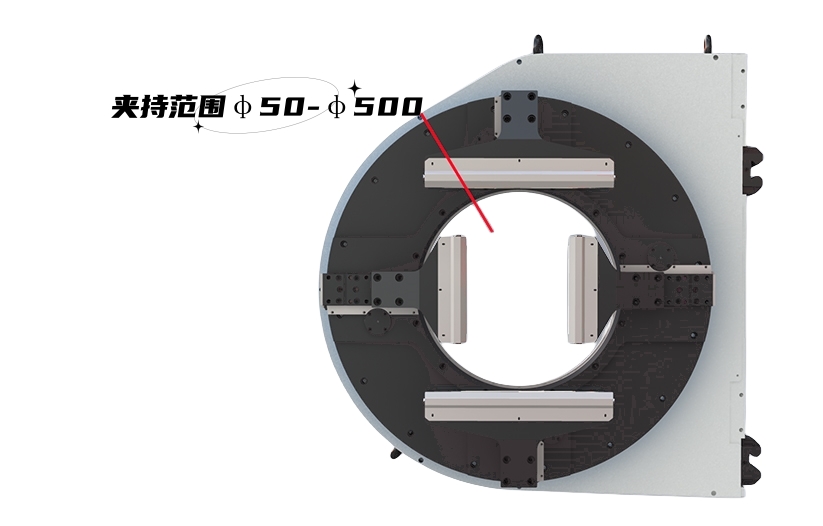

2、夹持范围:φ50-φ500mm。

3、通用卡盘设计。

4、三卡盘结构设计高效率。

5、零尾料切割无浪费。

6、整管上料 整管下料。

7、最大功率:120000W。

III. Introduction to the HT-TP Series Heavy-duty CNC Fiber Laser Pipe Cutting Machine:

The HT-TP series heavy-duty laser pipe cutting machine.

Clamping range: φ50-φ500mm.

Universal chuck design.

Three-chuck structural design for high efficiency.

Zero scrap cutting without waste.

Whole pipe loading and whole pipe unloading.

Maximum power: 120000W

四、产品介绍;

1、结构简单稳定,拥有良好的密封性及运动特性,可夹持方管、圆管、椭圆管、工字钢等材料。三卡盘加工模式,满足切割头在两卡盘之间切割尾料,使尾料的切割精度更高,

本激光切管机凭借对不同形状、不同规格管材高效率、高质量的加工性能,广泛应用于健身器材、汽车制造、保温容器、机械加工、不锈钢装饰、办公家具、农用机械、高空作业、五金制品等诸多行业。

IV. Product Introduction:

The structure is simple and stable, with good sealing performance and motion characteristics. It can clamp materials such as square pipes, round pipes, elliptical pipes, and I-beams. The three-chuck processing mode enables the cutting head to cut the remaining materials between the two chucks, achieving higher cutting accuracy for the remaining materials.

This laser pipe cutting machine, with its high-efficiency and high-quality processing performance for pipes of different shapes and specifications, is widely used in many industries such as fitness equipment manufacturing, automotive manufacturing, thermal insulation container production, mechanical processing, stainless steel decoration, office furniture manufacturing, agricultural machinery production, aerial work equipment manufacturing, and hardware product manufacturing。

2、负载大、范围大

激光切管机的三卡盘结构,可避免因管料高速旋转抖动而影响切割精度和效率。夹持范围大,高承载力卡盘,最大夹持范围可达500mm,最大承载可达2吨,更大填补重型管材切割需求,卡爪夹持力智能可调,夹持范围可根据管材范围快速更换。

2.Large load capacity and wide clamping range

The three-chuck structure of the laser pipe cutting machine can prevent the cutting accuracy and efficiency from being affected by the high-speed rotation and jitter of the pipe materials. It has a large clamping range. The high-load chuck can achieve a maximum clamping range of 500mm and a maximum load capacity of 2 tons, which can better meet the cutting requirements of heavy-duty pipes. The clamping force of the chuck jaws is intelligently adjustable, and the clamping range can be quickly adjusted according to the size of the pipes。

·

·

3、三卡盘结构 创新加工

1)三卡盘结构设计,加工过程采用三个卡盘夹持支撑,可对管材的弯曲、扭曲较大的管材调整夹持力进行矫正切割,可避免因管料后端抖动而影响前端切割精度,运行速度快、精度高、载重高。

3.Three-chuck structure for innovative processing

)With the design of the three-chuck structure, during the processing, three chucks are used for clamping and supporting. For pipes with significant bending and twisting, the clamping force can be adjusted for correction and cutting. It can prevent the jitter at the rear end of the pipe material from affecting the cutting accuracy at the front end. It features a fast running speed, high precision, and a high load-bearing capacity

·

·

2)重管多根上料 重载下料。

3)侧挂式导轨结构,防尘效果好;上料架型材上料,V型架接料,无需等待自动化程度高,质量最优。 对夹下料,可防止管材在运输和切割过程中滚动储料输送架,可存储多根管材,方便人员运输,节省时间。

2.)Multiple heavy pipes can be loaded and heavy-duty unloading can be carried out.

3.)The side-hung guide rail structure has a good dust-proof effect. The feeding rack is used for feeding with profile materials, and the V-shaped rack is used for receiving materials. There is no need to wait, and it has a high degree of automation and the best quality. The clamping unloading can prevent the pipes from rolling during transportation and cutting. The storage and conveying rack can store multiple pipes, which is convenient for personnel transportation and saves time

4)核心工艺 智能切割

5)采用MT智能切割系统,功能性更加完善和智能,提升蛙跳功能的速度和效率,集成快速穿孔模式及快速智能的穿孔模式,配置“航天天田”牌激光新一代工艺数据库,可对不同类型、不同形状的管材进行切割。重

4.)Core process for intelligent cutting

5.)The MT intelligent cutting system is adopted, making its functionality more complete and intelligent. It improves the speed and efficiency of the frog-jump function. It integrates a fast perforation mode and a fast and intelligent perforation mode, and is equipped with the laser new-generation process database of the "Amada" brand, which enables the cutting of pipes of different types and shapes

型激光切管机-性

五、HT-TP系列重载型数控光纤激光切管机技术参数(Technical Parameters of the HT-TP Series Heavy-duty CNC Fiber Laser Pipe Cutting Machine:):

型号 | HT-TP-12050 | HT-TP-9050 | HT-TP-12036 | HT-TP-9036 | HT-TP-L12050 |

加工范围 | φ50-508mm | φ50-508mm | φ50-360mm | φ50-360mm | φ50-508mm |

□50-350mm | □50-350mm | □50-260mm | □50-260mm | □50-350mm |

定位精度 | ±0.03mm/m | ±0.03mm/m | ±0.03mm/m | ±0.03mm/m | ±0.03mm/m |

重复定位精度 | ±0.05mm | ±0.05mm | ±0.05mm | ±0.05mm | ±0.05mm |

最大空运行速度 | 40m/min | 40m/min | 60m/min | 60m/min | 40m/min |

最大空转速度 | 50r/min | 50r/min | 80r/min | 80r/min | 50r/min |

单根管材最大质量 | 2000kg | 2000kg | 1200kg | 1200kg | 1500kg |

最大一次性下料尺寸 | 12000mm | 9000mm | 12000mm | 9000mm | 12000mm |

推荐功率段 | 3000W-80000W |

| Model | Processing Range | Positioning Accuracy | Repeat Positioning Accuracy | Maximum Idle Running Speed | Maximum Idle Rotation Speed | Maximum Mass of a Single Pipe | Maximum One-time Unloading Size | Recommended Power Range |

|---|

| HT-TP-12050 | φ50-508mm; □50-350mm | ±0.03mm/m | ±0.05mm | 40m/min | 50r/min | 2000kg | 12000mm | 3000W - 20000W |

| HT-TP-9050 | φ50-508mm; □50-350mm | ±0.03mm/m | ±0.05mm | 40m/min | 50r/min | 2000kg | 9000mm | 3000W - 20000W |

| HT-TP-12036 | φ50-360mm; □50-260mm | ±0.03mm/m | ±0.05mm | 60m/min | 80r/min | 1200kg | 12000mm | 3000W - 20000W |

| HT-TP-9036 | φ50-360mm; □50-260mm | ±0.03mm/m | ±0.05mm | 60m/min | 80r/min | 1200kg | 9000mm | 3000W - 20000W |

| HT-TP-L12050 | φ50-508mm; □50-350mm | ±0.03mm/m | ±0.05mm | 40m/min | 50r/min | 1500kg | 12000mm | 3000W - 20000W |

备注:本资料所列数据为参考数据,如与机床实际数据不符,应以机床实际数据为准,以上参数如有变动,恕不另行通知,本公司保留对此资料的最终解释权!

Remarks: The data listed in this document are for reference only. In case of any discrepancies between these data and the actual data of the machine tool, the actual data of the machine tool shall prevail. In case of any changes to the above parameters, no further notice will be given. Our company reserves the right to the final interpretation of this document!

·

· ·

·