价格低廉:这是经济型校平机最显著的优势。它的制造成本相对较低,价格通常只有高端或专业型校平机的几分之一甚至更低,能让预算有限的中小企业以较低成本获得板材校平能力,降低了生产设备的采购门槛。

操作简便:经济型校平机的设计通常较为简单,操作界面简洁明了,易于上手。不需要操作人员具备复杂的专业知识和长时间的培训,普通工人经过短期培训即可熟练操作,减少了人工成本和培训时间。

维护成本低:其结构简单,零部件数量相对较少,且大多采用常见的通用零部件,维修保养容易,配件价格也较为便宜。在设备出现故障时,能够快速进行维修,降低了维修成本和停机时间,提高了生产效率。

适用性强:虽然是经济型校平机,但它仍能满足一般板材加工企业的基本校平需求,可对多种材质、不同厚度的板材进行校平,如常见的低碳钢、不锈钢、铝板以及一些塑料板材等,适用范围较广,能在一定程度上满足不同用户的多样化需求。

经济性校平机通过对金属和非金属板材的校平,能够满足不同行业对板材平整度的要求,提高产品质量和生产效率,同时因其经济性,适用于对成本较为敏感的中小企业或对校平精度要求不是极高的一般性生产加工场景。

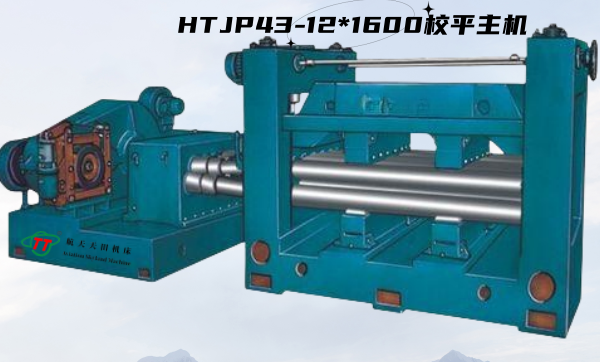

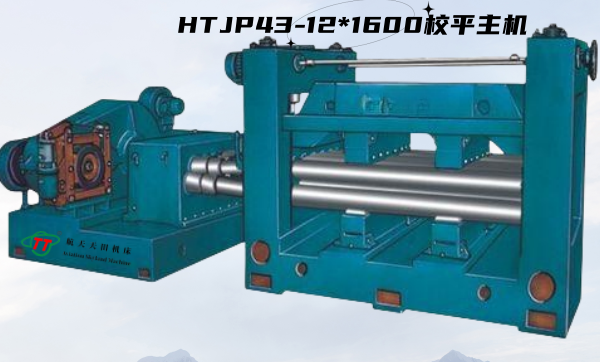

这是一款经济型板材校平机型,可以通过上下对辊平整板材,主机采用7-11工作辊,实心工作锻造辊,经过调制处理后再进行深层镀铬处理,表面光洁度很高,在整个平板过程中使板材平整推进,下端工作辊两边配有辅助支承辊易于调节,从而达到平板效果,精度控制在每平米土1毫米以内,前段可选配一套简易送料机构,后面再配备一台便于剪切的液压经济型数控剪板机,可以实现自动计数剪切,使得整套机器完全控制自动运行,真正达到数控自动化,这也是经济实惠的一种推荐机型。

I. The economical leveling machine is suitable for the processing of various fields and materials. The main applicable scopes are as follows:

It is used for leveling the components such as the body plates, engine hoods, and vehicle doors of automobiles. It ensures the flatness of the plates, which is beneficial for subsequent processes such as stamping and welding, and improves the quality and assembly accuracy of automobile parts.

It levels the metal plates used for the casings of electronic equipment, such as computer cases and mobile phone casings. It guarantees the flatness and aesthetic appearance of the casings, and is also conducive to improving the heat dissipation performance and overall quality of the electronic equipment.

It levels various metal plates used for furniture manufacturing, such as the panels and frames of tables and chairs, as well as the side panels and door panels of filing cabinets. It makes the surface of the furniture smooth and flat, enhancing the appearance quality and usability of the furniture.

In the field of architectural decoration, it can be used to level various metal decorative plates, such as aluminum single panels and stainless steel decorative plates. It enables these plates to be better applied in projects such as exterior wall decoration, interior ceiling, and partition of buildings, enhancing the decorative effect.

For plastic plates that require high-precision flatness, such as plastic decorative plates and plastic packaging plates, the economical leveling machine can level them, improving the flatness of the plates to meet the needs of different application scenarios.

In the production of rubber products, the leveling machine can be used to level rubber plates, providing flat plates for subsequent processes such as cutting and forming, and improving the quality and dimensional accuracy of rubber products.

Compared with other types of leveling machines, the economical leveling machine has the following advantages:

This is the most prominent advantage of the economical leveling machine. Its manufacturing cost is relatively low, and the price is usually only a fraction or even lower than that of high-end or professional leveling machines. It enables small and medium-sized enterprises with limited budgets to obtain the plate leveling ability at a lower cost, reducing the procurement threshold of production equipment.

The design of the economical leveling machine is usually relatively simple, and the operation interface is concise and clear, making it easy to use. Operators do not need to have complex professional knowledge or undergo long-term training. Ordinary workers can operate it proficiently after short-term training, reducing labor costs and training time.

Its structure is simple, with a relatively small number of components. Most of the components are common and universal, making maintenance easy, and the price of accessories is relatively low. When the equipment breaks down, it can be repaired quickly, reducing maintenance costs and downtime, and improving production efficiency.

Although it is an economical leveling machine, it can still meet the basic leveling needs of general plate processing enterprises. It can level plates of various materials and different thicknesses, such as common low-carbon steel, stainless steel, aluminum plates, and some plastic plates. Its wide applicable range can meet the diverse needs of different users to a certain extent.

The economical leveling machine levels metal and non-metal plates, meeting the flatness requirements of different industries, improving product quality and production efficiency. At the same time, due to its economy, it is suitable for small and medium-sized enterprises that are sensitive to costs or general production and processing scenarios where the requirement for leveling accuracy is not extremely high.

This is an economical plate leveling machine. It can level plates through the upper and lower opposing rolls. The main machine is equipped with 7-11 working rolls, and the solid working forged rolls are deeply chrome-plated after being quenched and tempered. The surface finish is very high. During the whole plate leveling process, the plates are smoothly pushed forward. Both sides of the lower working rolls are equipped with auxiliary support rolls, which are easy to adjust, so as to achieve the plate leveling effect. The precision is controlled within ±1 millimeter per square meter. A set of simple feeding mechanism can be optionally configured at the front end, and a hydraulic economical numerical control shearing machine that is convenient for shearing can be equipped at the back. It can realize automatic counting and shearing, making the whole set of machines operate automatically under full control, truly achieving numerical control automation. This is also a recommended model with high cost-effectiveness.

二、HTJP43系列经济型校平主机常用规格(II. Commonly used specifications of the HTJP43 series economical leveling main machine):

| 规格参数 | 描述 |

|---|

| 可加工板材厚度 | 通常为 0.5 - 6mm(不同型号有所不同) |

| 可加工板材宽度 | 1000mm、1250mm、1500mm 等常见规格 |

| 校平辊数量 | 一般为 7 - 11 根 |

| 校平精度 | 平面度可达 ±0.1 - ±0.5mm/m²(根据板材材质和厚度有所不同) |

| 工作速度 | 5 - 20m/min 左右 |

| 电机功率 | 主驱动电机 3 - 7.5kW,其他辅助电机功率根据具体配置而定 |

| 机器重量 | 1 - 3 吨左右 |

| 外形尺寸(长 × 宽 × 高) | 约 3000mm×1500mm×1800mm(因型号而异) |

| 配置 | - 校平辊:通常采用优质合金钢制造,表面淬火处理,硬度高、耐磨性好。

- 驱动系统:采用电机通过减速机带动校平辊转动,保证稳定的动力输出。

- 上下料装置:简单的手动或半自动上下料平台,方便板材的装卸。

- 控制系统:基本的电气控制系统,可实现电机的启动、停止、调速等功能,部分型号可能具备简单的故障诊断和报警功能。

- 机身结构:采用焊接钢结构,经过时效处理,具有较高的强度和稳定性。 |